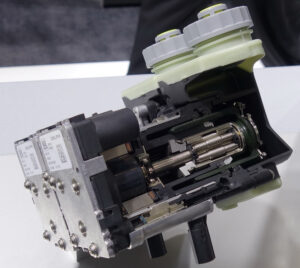

In close cooperation with Joma-Polytec and Mercedes-Benz Fuel Cell, a subsidiary of Daimler AG, the engineering plastic Ultramid has successfully been used to manufacture a number of fuel cell system components. This innovative solution is being used as standard in the new Mercedes GLC F-CELL, which combines a fuel cell with a rechargeable lithium-ion battery.

For the Mercedes GLC F-CELL, it is the all-round excellence of Ultramid’s properties that counts: good thermal and chemical resistance, dynamic stiffness, impact strength, and good long-term performance.

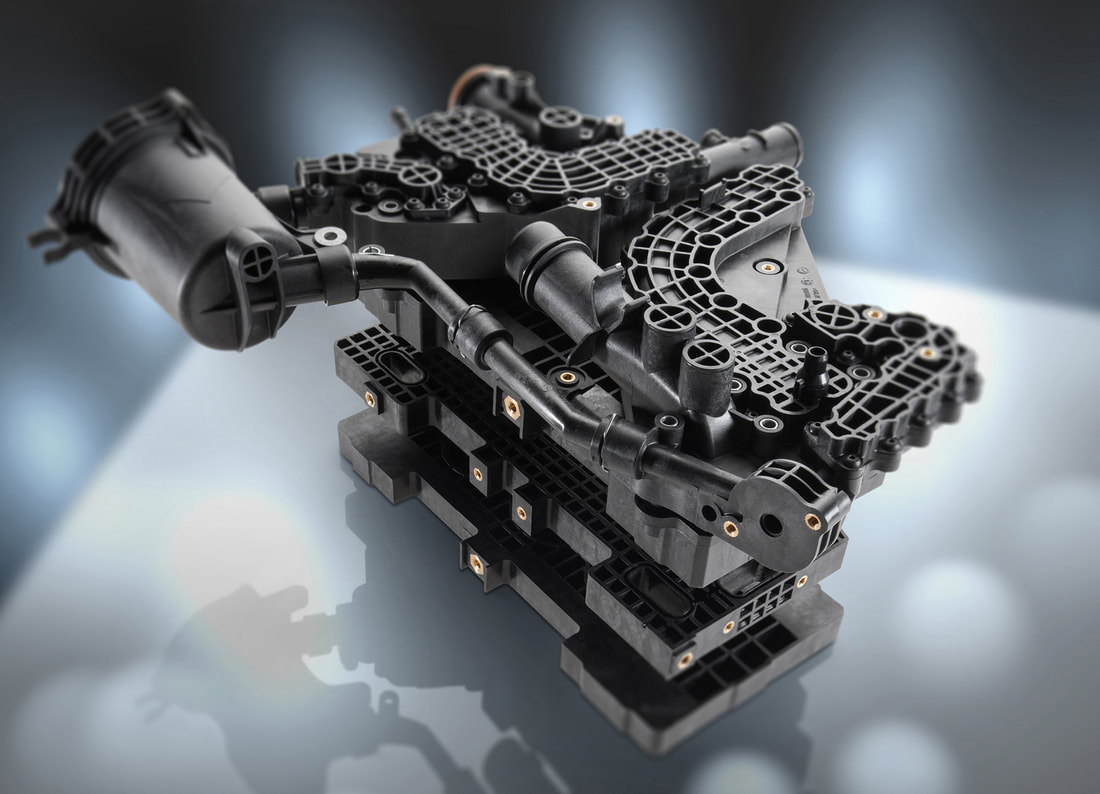

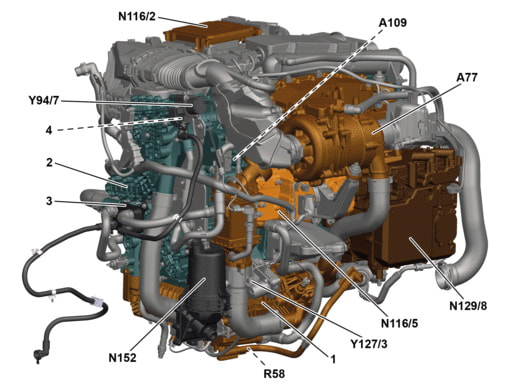

The hydrogen recirculation loop is completely integrated into the media port side of the fuel cell stack enclosure. The recirculation of hydrogen is ensured by a passive ejector system.

The media distribution plate is the interface at the fuel cell stack for air and hydrogen as well as high-temperature coolant. The jet pump (4) for the hydrogen supply is integrated in the media distribution plate.

Two glass fiber-reinforced Ultramid grades (A3WG10 CR and A3EG7 EQ) are now being used as standard to manufacture the anode- and cathode-end plate in fuel cells. Ultramid A3EG7 EQ is an ideal material, given the exceptional purity requirements associated with sensitive applications in the electronics industry. In the case of the media distribution plate and the water separator unit, which is exposed to a wide variety of media through the cooling water, air and hydrogen channel, this Ultramid grade offers excellent resistance, while at the same time meeting all requirements regarding the purity of the material.