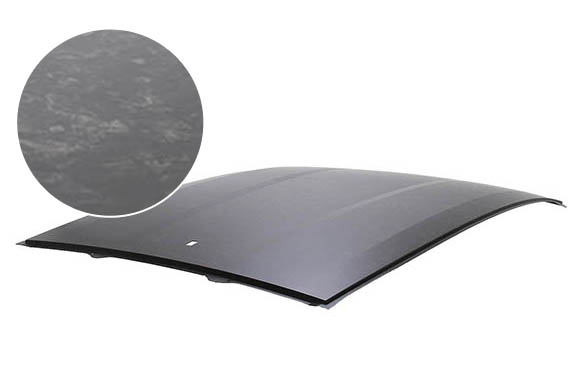

Developed by MCC, this SMC is a type of intermediate material for CFRPs, and takes the form of a sheet-shaped material in which carbon fibers cut into several-centimeter lengths are dispersed in resin. The SMC can be processed into components in a short period of time, i.e., roughly two to five minutes, by press molding. In contrast to prepreg intermediate materials (uncut carbon fiber fabric impregnated with resin), this SMC features high formability for molding complicated shaped parts. Also, since the SMC’s mechanical properties are almost homogeneous, manufacturers can use carbon fiber with relative ease and achieve weight reduction and high strength while utilizing previously accumulated expertise in component design.