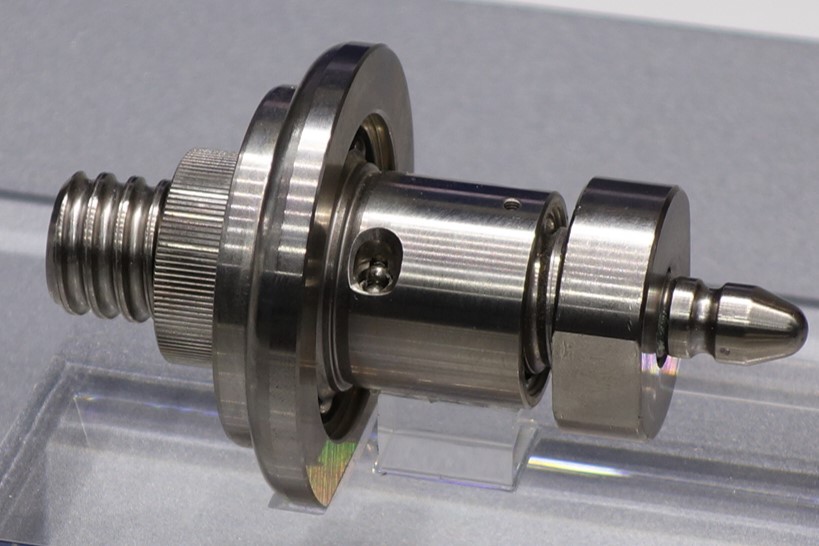

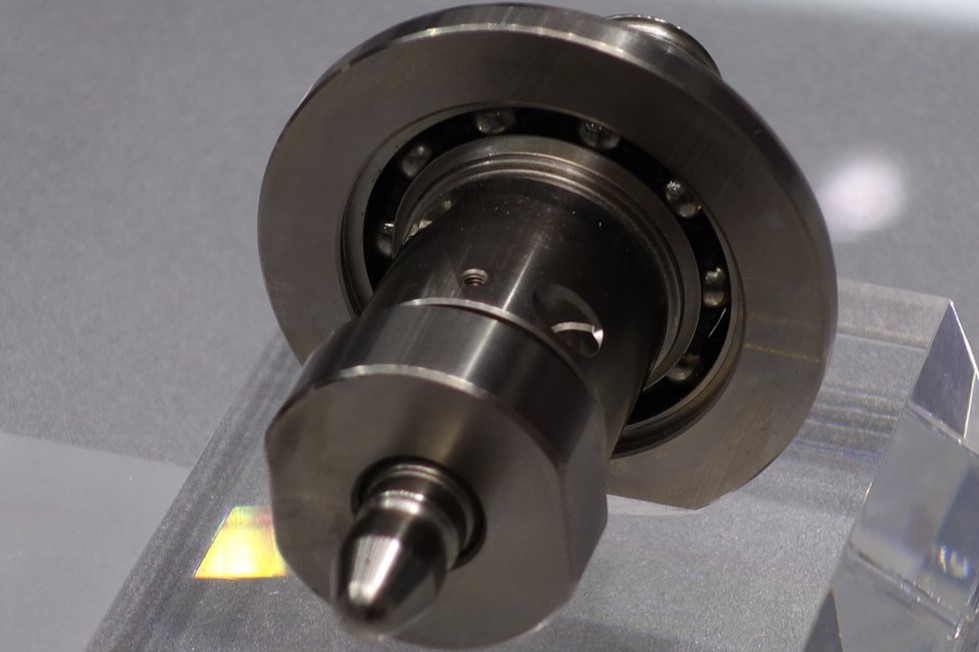

Ball screw drive (BSD) for electro-mechanical brake booster

High efficiency

Very low friction

Reduction of fuel consumption and CO2 emissions brake booster systems compared to a conventional brake system (power on demand)

Design with optimized noise characteristics

Can be supplied clearance-free if required

Maintenance-free throughout the entire operating life

Comfort and safety functions can be integrated on brake system level (autonomous driving, emergency brake etc.)

Transforms the rotational motion of an electric motor into translational motion of the actuator

Transforms small drive torques into large output forces

Available with rotating spindle or with rotating nut

Customer-specific design solution optimized for installation space, loads, to system costs and system performance

Integration of adjacent components possible, e.g. bearing, piston, etc.

BSD manufactured with high-precision forming methods for complex system requirements