NSK-Warner K.K.

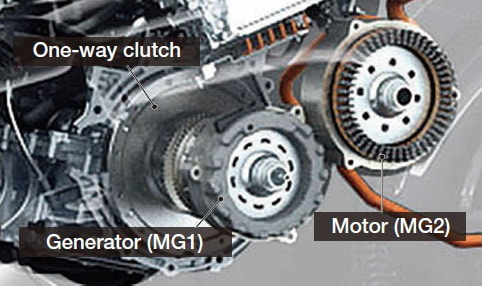

A new PHV transaxle aims for the EV driving force. To achieve this, a one-way clutch is placed between the engine and power split device realizing the dual motor drive system, which enables the vehicle to be driven using two motors.

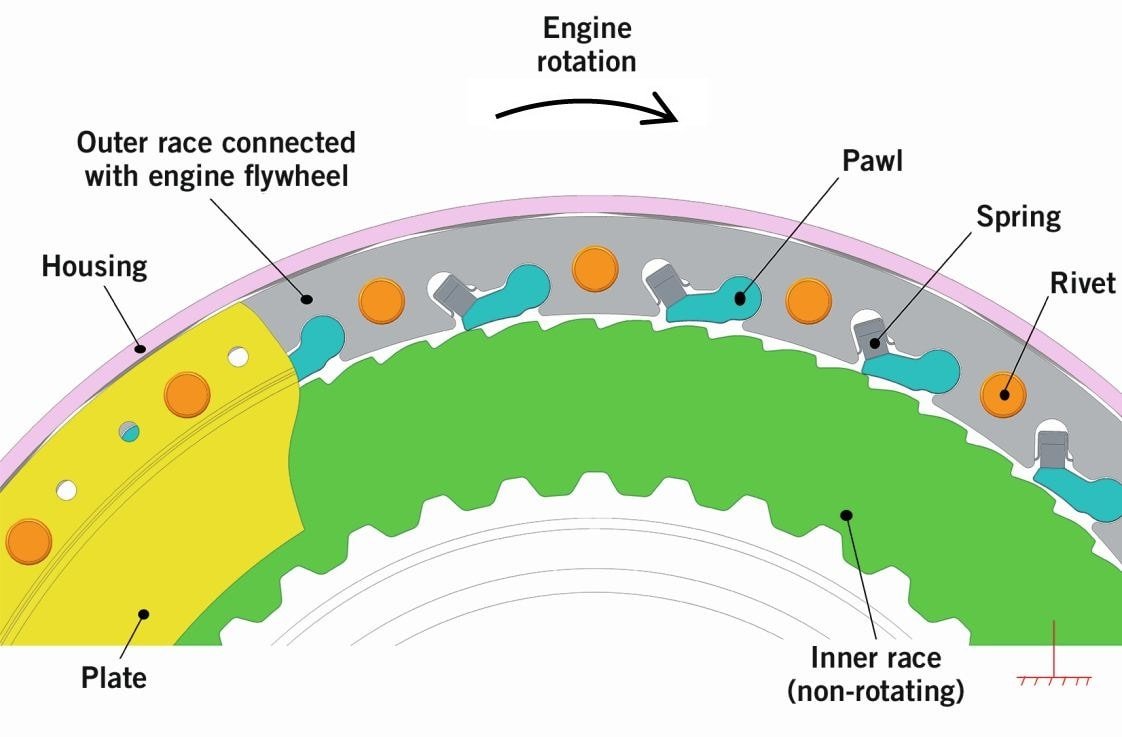

The clutch is applicable to a lubricant-free environment because it uses pawls that do not touch the inner ring when idle running, and the component parts such as the pawls and inner and outer rings are coated with solid lubricant.

To avoid ratchet noise the engine speed of separation of the pawls and inner race was designed around 400 rpm, which is significant lower than the engine idling speed of approximately 1000 rpm. As pawls and inner race are not in contact while in HV mode, this design also minimizes the drag torque (loss associated with dragging) of the one-way clutch.

A thin structure of the one-way clutch with a high torque capacity was achieved by a mechanical one-way clutch with pawls that does not increase friction.

Backlash, which was one of the problems with ratchet-type (pawl-type) clutches, has been reduced substantially by changing the phase of engagement between pawls.