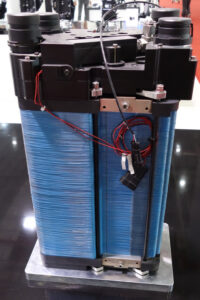

The high-voltage connector for new energy vehicles reduces costs by replacing copper with aluminum and electroplating with nickel sheets, and mica tape can be wound as needed to prevent thermal runaway.

Highlights

- Aluminum busbars, low cost, lightweight design

- The internal wrapping of mica + PVC can improve production efficiency

- Thermocompression bonding process, the positive and negative busbar insulation films are bonded together

- Meets the flame retardant grade UL94 V-0 and meets the fireproof and pressure resistance requirements of insulation materials in the case of thermal runaway

Features

- Own in-house processes for insert molding busbar, extruded busbar, diffusion welding flexible busbar, powder coating busbar, plastic dip busbar, and thermally laminated stacked busbar

- Meet the requirement of flame retardant and safety after thermal runaway

- Apply widely on EV and solar power system

Market Prospects: Flame retardant & fire-proof material can meet the safety requirements after thermal runaway. The laminated busbar does not require tooling, and copper conductors can reduce the weight and lower the cost, and they can meet the market demands.