The Durethan-brand polyamide 6 compounds from LANXESS are not only cost-effective alternatives to polyamide-66-based compounds but are also much more climate-friendly. This is according to calculations performed by the specialty chemicals company based on its own data and on figures published by a range of institutions including various associations of the plastics industry.

The carbon footprint of the polyamide 6 compounds from LANXESS can be reduced even further by producing them not from conventional glass fibers, but from the resource-conserving Eco glass fibers developed by the company. Industrial glass waste is used in their production, which reduces the consumption of raw materials and energy and avoids waste. LANXESS offers the corresponding compounds that are mass-balanced in accordance with ISCC Plus (“International Sustainability and Carbon Certification”) under the brand name Durethan ECO. They contain up to 60 percent by weight of recycled fiber. Mass balancing helps to determine the share of sustainable material in the compound and to indicate it in a transparent manner for processors.

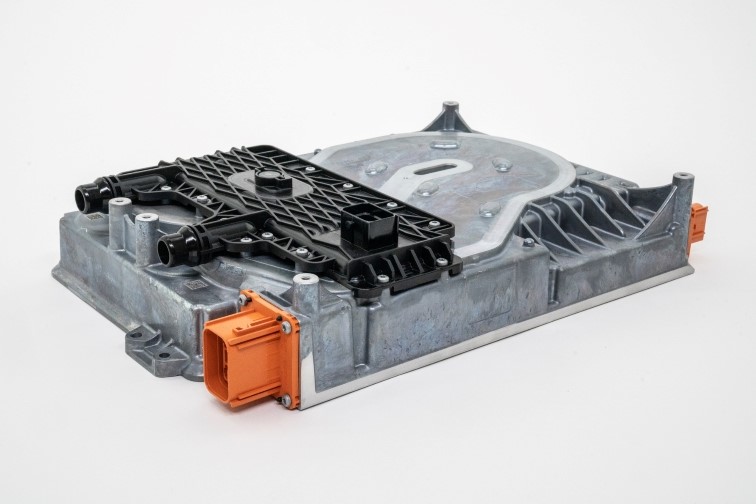

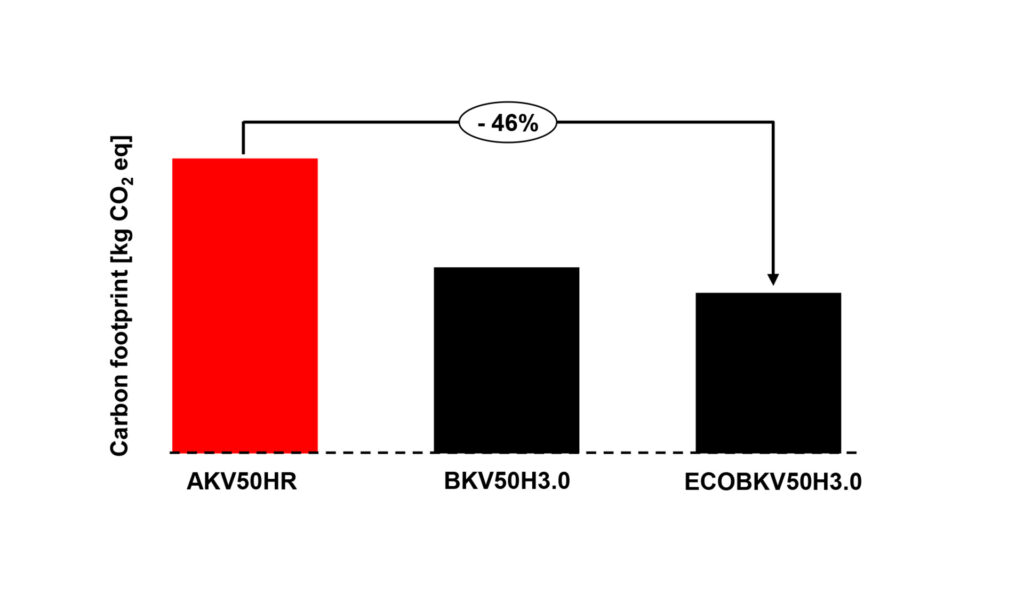

The extent to which the carbon footprint can be reduced is demonstrated by the cover for an on-board battery charger installed in an all-electric compact vehicle made by a German carmaker. It consists of Durethan BKV50H3.0, which is highly reinforced with 50 percent by weight of short glass fibers.

The use of a BKV50 type with Eco glass-fiber reinforcement could potentially have reduced the carbon footprint of the battery charger cover by 46 percent compared with a component made from polyamide 66 with conventional glass fibers in the same quantity.

Under the name HiAnt, LANXESS offers a range of services designed to support customers in the transition from polyamide 66 to polyamide 6. These services range from joint concept development for the design of components and material optimization through to cutting-edge methods in computer-aided engineering (CAE) for predicting component properties.