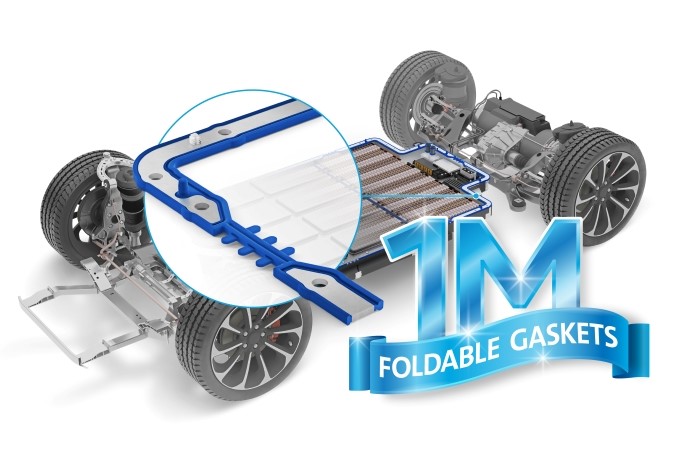

By developing the foldable gasket, Freudenberg Sealing Technologies has found a solution that meets customer requirements to the highest degree.

A segmented aluminum carrier with multiple sealing profiles on the outer edge provides strength while also integrating plastic retention fixtures. These are used to attach the gasket quickly and efficiently to the battery housing cover. The carrier segments are interconnected with a continuous sealing profile that is highly flexible. This way it can compensate for small manufacturing tolerances in the housing.

As a result, the foldable gasket helps make the battery system more reliable and durable. Its simple disassembly also makes it easy to service and repair the battery. This benefits both the vehicle owners and the environment: Instead of having to replace the battery, it can be reused.

The foldable gasket is delivered as a single complete unit that doesn’t first have to be assembled from individual elements, which greatly increases the reliability of the installation. Furthermore, battery manufacturers can use fully automated, robotic gasket installation on site. Another significant advantage of this solution is that the metallic inserts ensure high electrical conductivity between the battery housing and cover. This is important for efficient shielding of the electromagnetic fields generated by the current flow in the battery. Otherwise, these fields could interfere with other electronic components in the car.

Despite its large dimensions when installed, the gasket is produced on a small press in Langres. This keeps the amount of energy required for its production relatively low. Additionally, this foldable version facilitates the use of standard-sized packaging solutions, resulting in space savings and, consequently, a reduction in energy consumption during transportation.

The foldable gaskets made by Freudenberg Sealing Technologies use standard elastomers such as silicones and EPDM that meet safety-related flame resistance standards. Combined with an innovative design, these gaskets meet the strictest sealing requirements according to IPX-9K, IPX-7X standards, as well as other global specifications. Moreover, these foldable versions are suitable for all combinations of materials used for the battery cover and housings, such as aluminum, steel and composite materials.