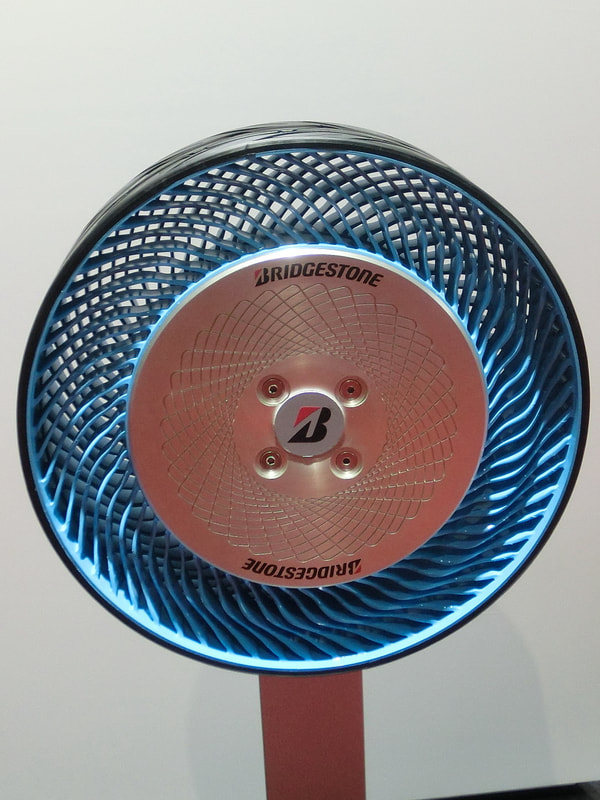

With a unique structure of spokes stretching along the inner sides of the tires supporting the weight of the vehicle, there is no need to periodically refill the tires with air, meaning that the tires require less maintenance. At the same time the worry of punctures is eliminated. In addition, the spoke structure is made from thermoplastic resin (A synthetic resin that becomes flexible when heated, can be processed into a variety of shapes, and becomes hard when cooled.) and, along with the rubber in the tread portion, the materials used in the tires are recyclable, contributing to the efficient use of resources.

Sumitomo Rubber Industries’s “GYROBLADE” technology takes the form of a tire tread affixed to the circumference of a tire body that is composed of a metallic wheel surrounded by special resin spokes, producing a tire that fulfills all of the basic functions (Supporting the Weight of a Vehicle, Transferring Driving and Braking Power to the Road, Absorbing and Dampening Shock Maintaining and Changing Vehicle Direction) of a tire without requiring inflation. This advancement not only removes safety concerns arising from underinflated tires due to punctures or inattention while greatly reducing maintenance work, but also contributes to the environment by eliminating the need for spare tires. Not only that, but with the special resin spokes available in a wide variety of different colors, this new technology also enables tires to make a fashion statement.