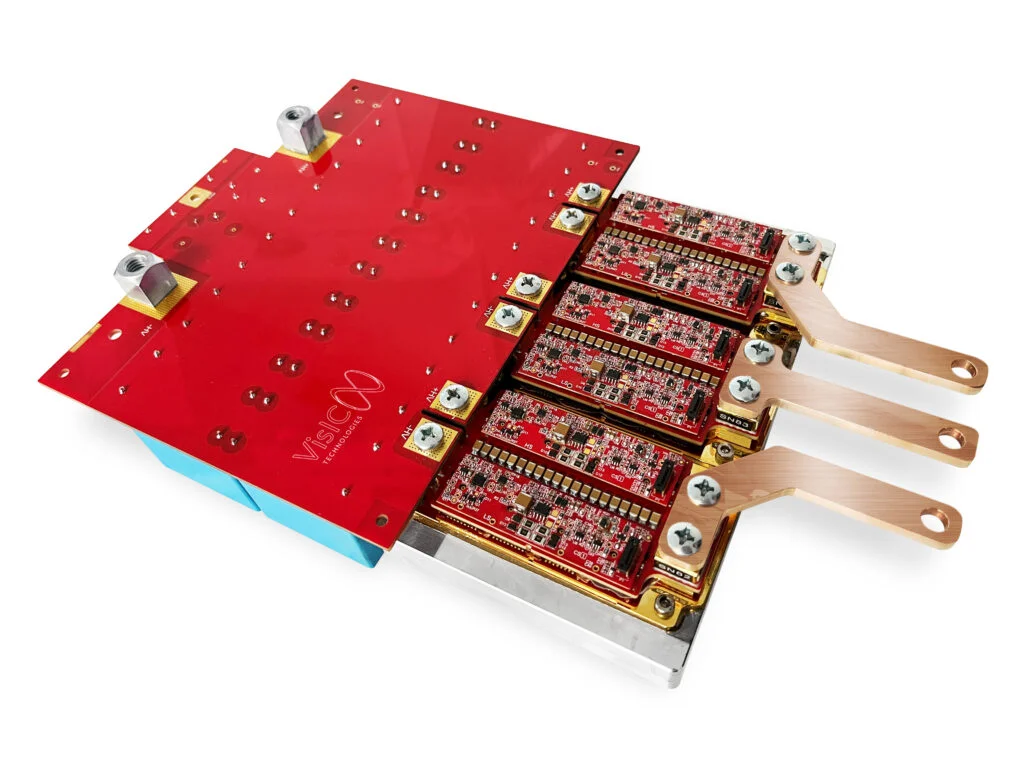

VisIC Technologies Ltd. successfully tested its 2.2mΩ 650V half-bridge power module, consisting of 4 parallel 8mΩ Power FET, in a 3-phase configuration on a dyno-test-bench using a PMSM motor at a major automotive OEM.

Thanks to this, VisIC Technologies has proven that their D3GaN (Direct Drive D-Mode Gallium-Nitride) semiconductor technology is well-suited even for the most challenging high-power automotive applications. Concerns about parallelization and oscillations caused by fast-switching transients have been addressed.

The inverter phase current reached 350Arms (500A peak) at 400V, although test system set-up limitations prevented higher currents, which the 2.2mΩ Power Module is capable of.

WLTP driving cycle testing was executed and achieved comparable efficiency with commercial Silicon Carbide-based modules, despite using early non-optimized module prototypes. This means that D3GaN will deliver its promise of the highest efficiency, improving car costs through lighter, smaller power systems and a smaller battery size, without compromising the car’s driving range. In addition, the D3GaN technology, based on GaN-on-Silicon semiconductor process, is delivering better than Silicon Carbide (SiC) performance at the more competitive Silicon cost level.

VisIC Technologies 3-phase prototype inverter system will be available for testing across additional customer sites towards the end of the 2nd quarter of 2023.