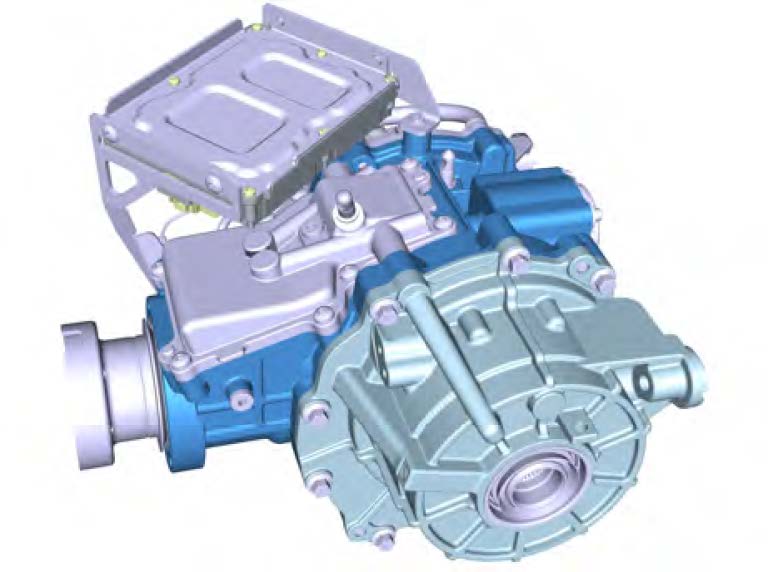

GKN developed a new version of its Twinster torque vectoring all-wheel drive (AWD) system for the Ford Focus RS. An innovative combination of new gearing ratios and control algorithms over-speed the rear wheels.

Over-speeding the rear wheels alters the way the car feels and handles. In curves, the Twinster makes the vehicle turn in more sharply, responding more immediately to the driver’s inputs. And in Ford’s drift mode, the AWD system delivers even more torque to the rear axle, delivering enough torque to the rear wheels for the RS to achieve a controlled “drift” through corners.

GKN Automotive’s software contains a unique subsystem that modifies the torque controls in ways that make it easier to induce on-throttle over-steer and then maintain side-slip angle while counter steering. Creating the desired yaw behaviour is a combination of calibration changes that modify the level of torque applied, how quickly it gets applied, and how much difference is created between the inner and outer rear wheels.

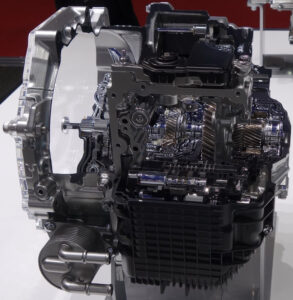

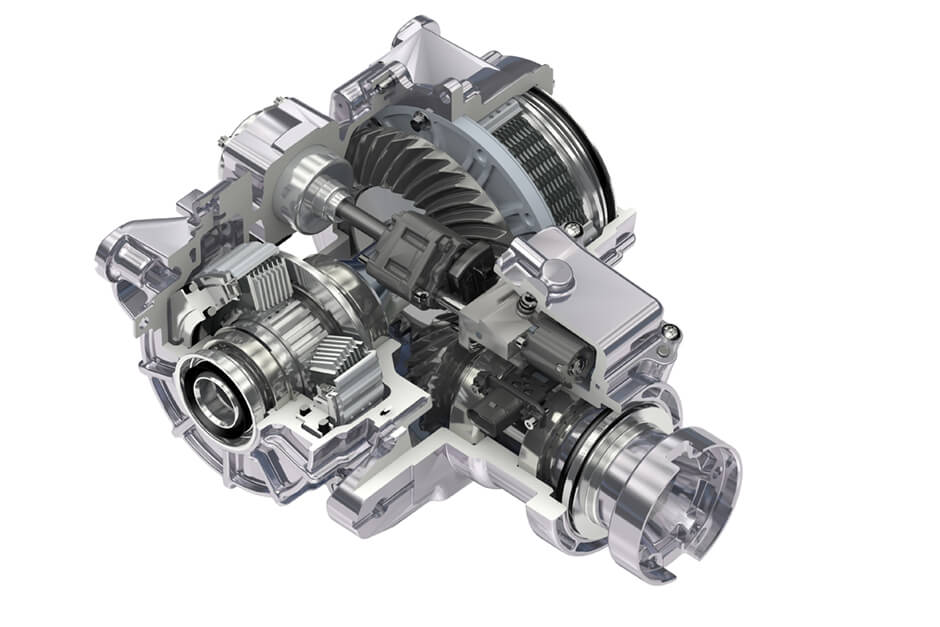

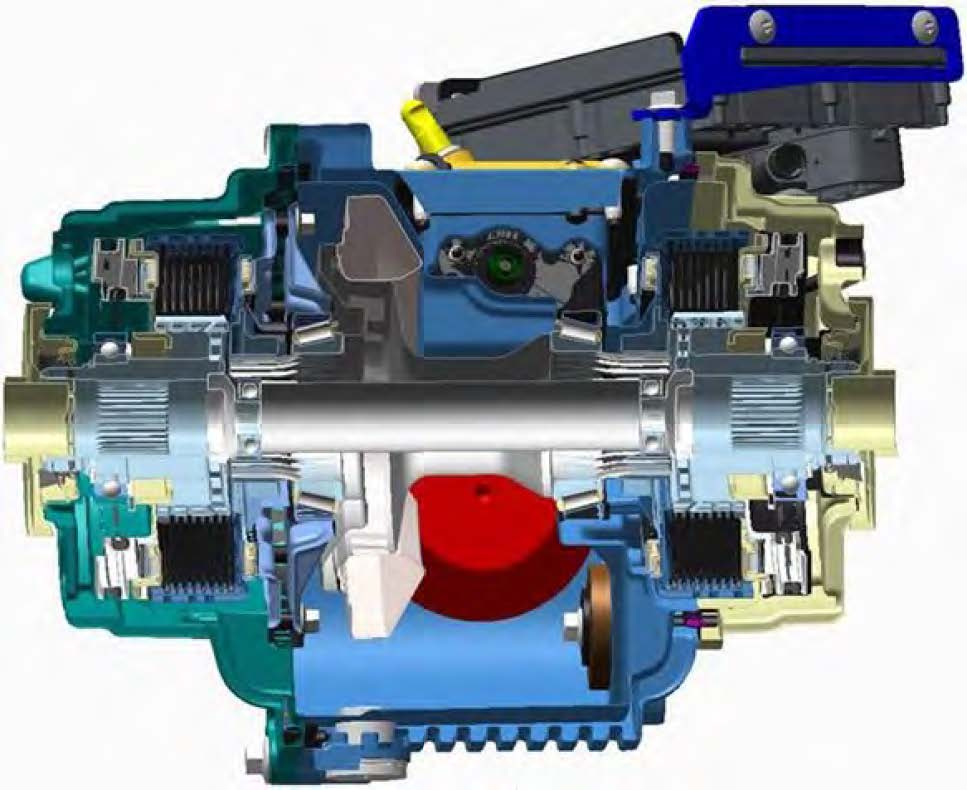

The rear drive unit contains two multi-plate clutches which are able to transmit engine torque to the rear wheels. The two clutches can be actuated on a wheel-specific basis using an electro-hydraulic servo drive and two control valves.

The electro-hydraulic servo drive uses a 3-phase, brushless electronically controlled DC (direct current) motor. The motor is connected to a pump that provides the line pressure for two control valves.

The two control valves are used to pressurize the clutches and transmit engine torque to the rear wheels. The control valves are actuated using a PWM (pulse width modulation) signal voltage.