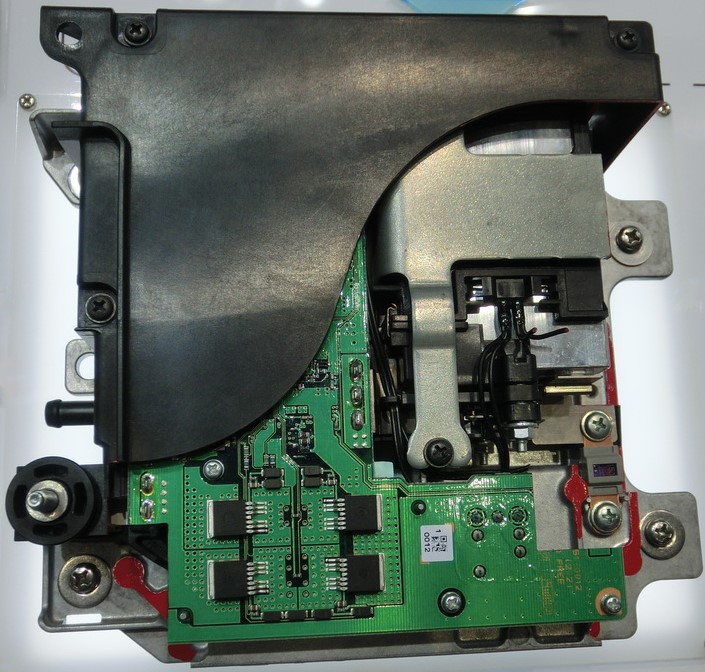

MAHLE is thus solving a problem existing since the invention of the cooled piston itself. Thick walls have poor heat dissipation and produce high temperatures at the bowl rim. On the other hand thin walls can lead to undesired high temperatures at the inner wall of the piston gallery, causing a layer of oil carbon to form. This acts as a thermal insulator and promotes due to excessive operating temperatures undesired wear and damage to the piston and cylinder liner.

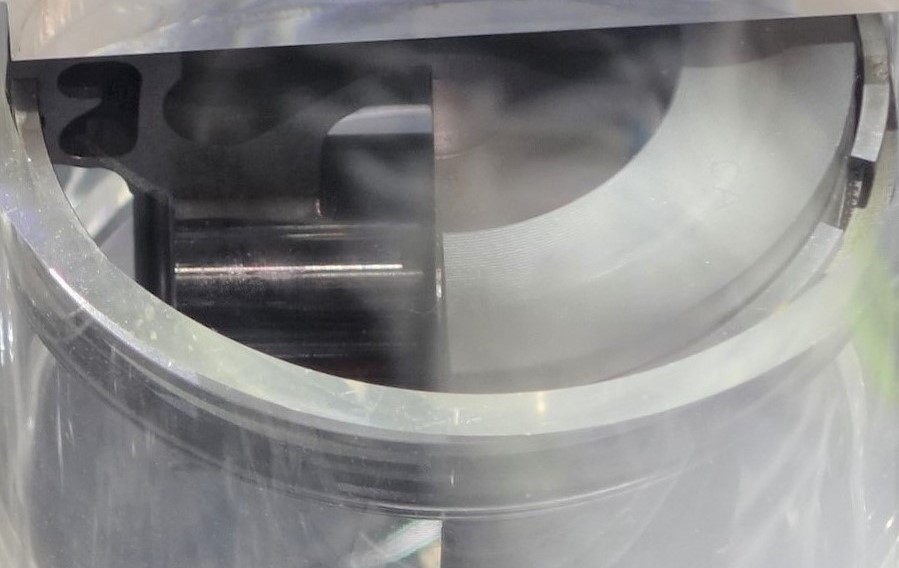

The solution: a piston gallery with a kidney-shaped cross section that guides the cooling oil flow in an optimal hydraulic path and ensures uniform heat dissipation that makes overheating impossible.

Such a design is only feasible, however, using the laser welding process developed by MAHLE. It is typical to use friction welding to produce pistons, but the material buildup in the cooling channel hinders the controlled guidance of the cooling oil flow.