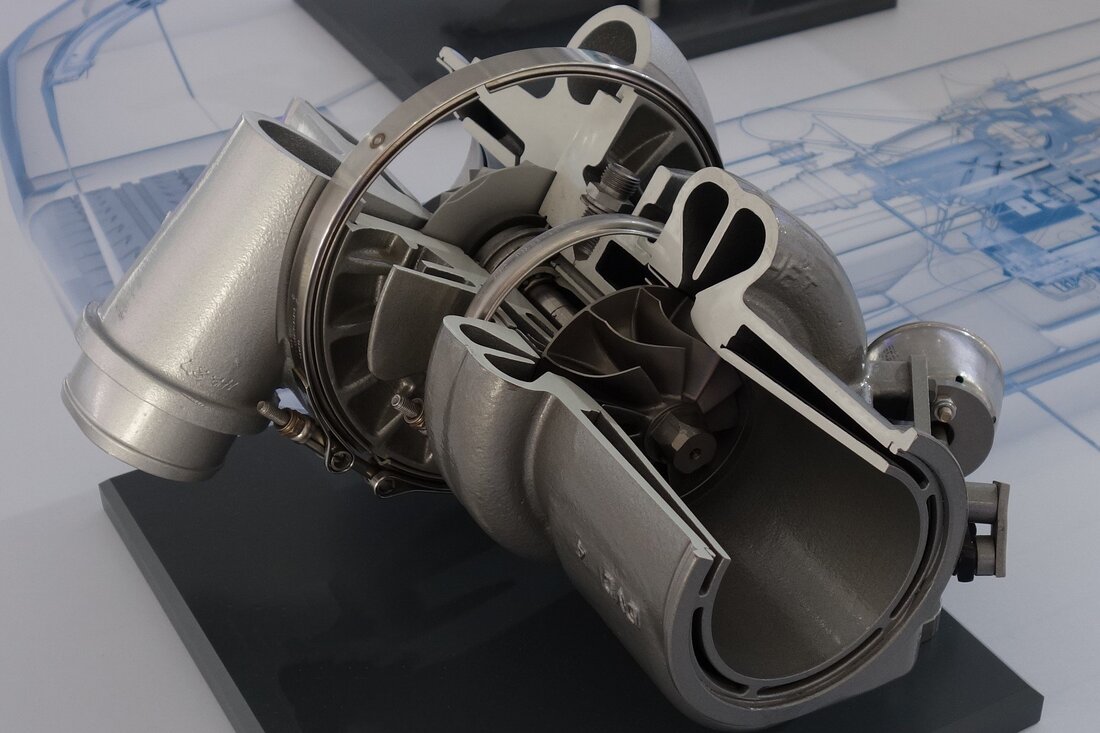

The core of the HET is the Gen3 ball bearing system, which was specifically developed to endure the rigorous environment and long lifetime required by heavy duty applications.

Ball bearing system enables tighter cover clearances for improved efficiency

Ball bearing used for reduced friction and improved low end torque responsiveness

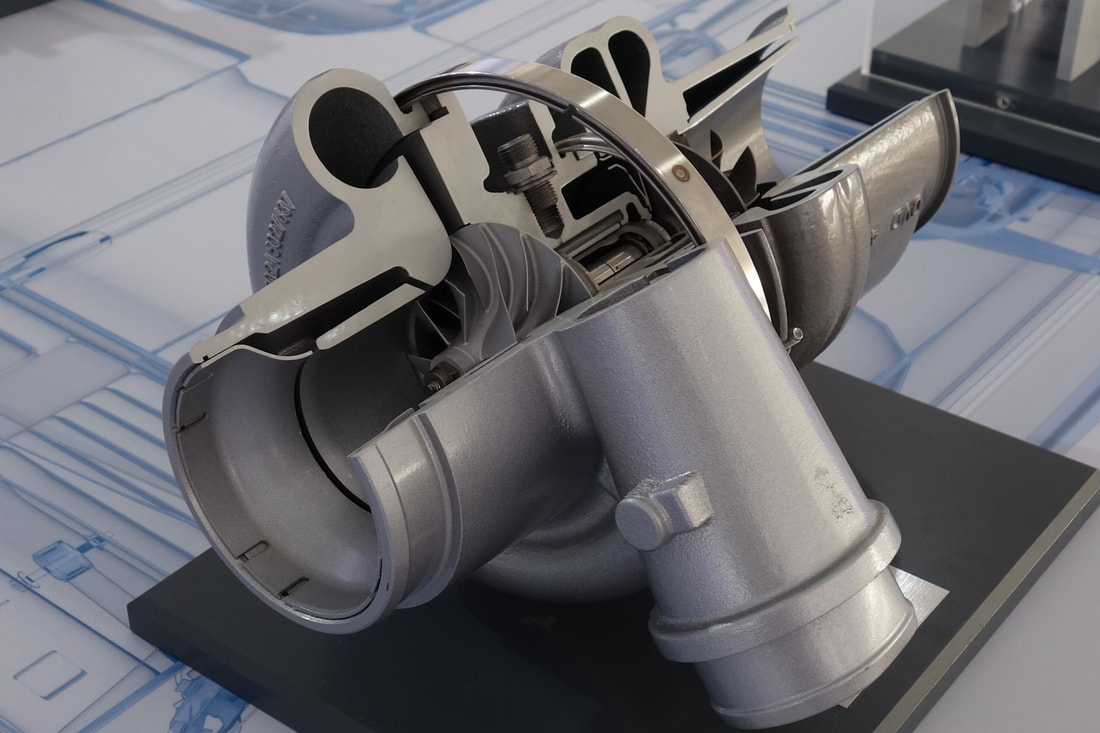

Journal bearing used for exhaust gas recirculation (EGR) applications

New center section design eliminates water cooling and minimizes heat transfer to bearings and compressor

New exhaust diffuser insert improves turbine as well as wastegate performance

Turbine stage design enables wastegate opening with minimal efficiency drop-off

Ball bearing used for reduced friction and improved low end torque responsiveness

Journal bearing used for exhaust gas recirculation (EGR) applications

New center section design eliminates water cooling and minimizes heat transfer to bearings and compressor

New exhaust diffuser insert improves turbine as well as wastegate performance

Turbine stage design enables wastegate opening with minimal efficiency drop-off

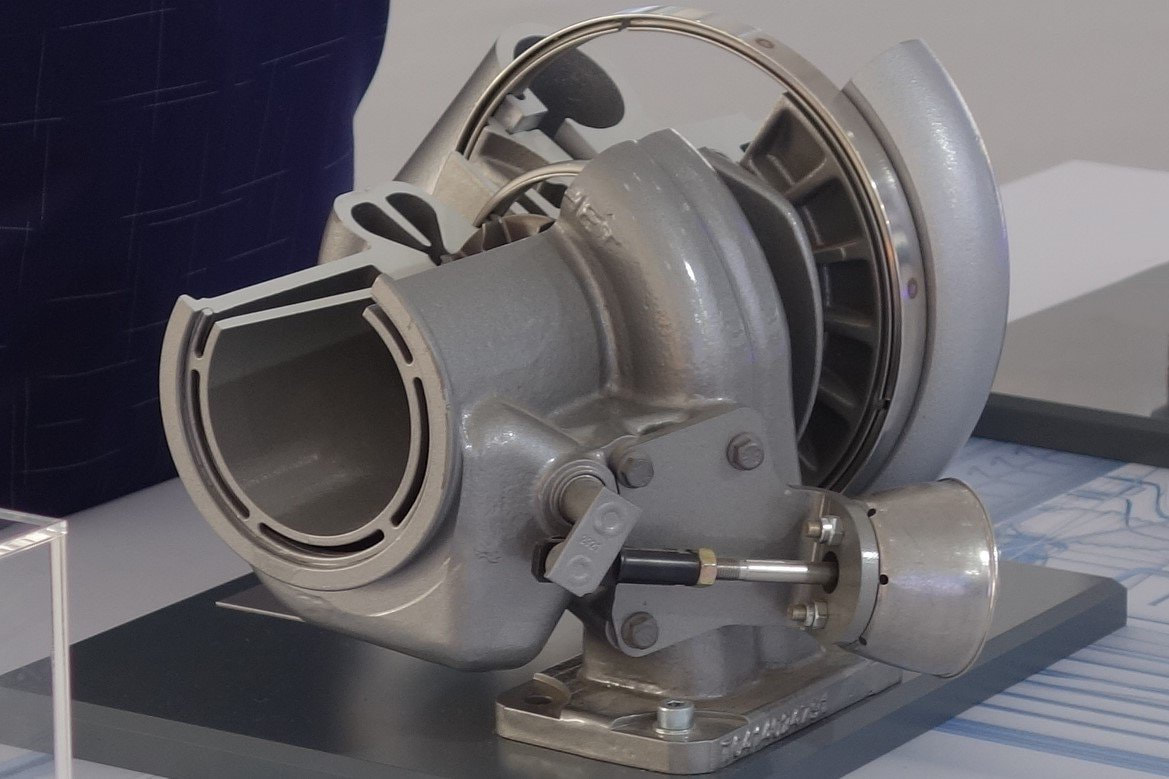

Optimized high efficiency compressor and turbine stages

Best thermodynamic and mechanical efficiency for heavy duty engines

Turbine performance can be tailored to application match and performance goals

Significant improvement in Time to torque (TTT)

Suitable for heavy- and medium duty applications

Best thermodynamic and mechanical efficiency for heavy duty engines

Turbine performance can be tailored to application match and performance goals

Significant improvement in Time to torque (TTT)

Suitable for heavy- and medium duty applications