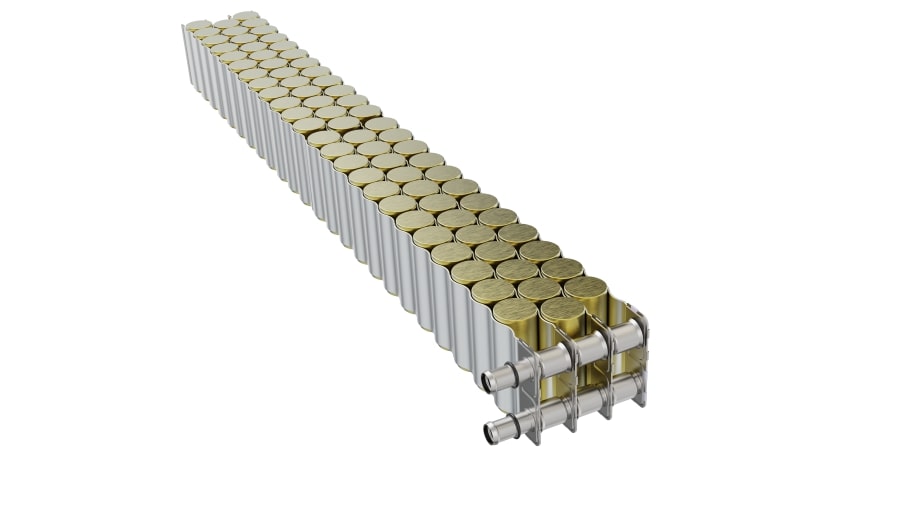

BorgWarner will supply a major German vehicle manufacturer in Europe and the U.S. with innovative battery cooling plates destined for the carmaker’s next generation of electric vehicles. Compared to alternative solutions, the BorgWarner cooling plates provide cooling capacity in a more compact package with reduced weight and cost. The plate design also compensates for assembly tolerances.

“We’ve collaborated with this customer for more than 30 years as a technical partner, contributing to many new technologies that the customer has integrated into its vehicles,” said Joe Fadool, President and General Manager, BorgWarner Emissions, Thermal and Turbo Systems. “We’re proud to extend our relationship by designing cooling components for the battery systems in their latest electric vehicle development platforms.”

New products capitalize on thermal expertise gained from exhaust gas recirculation (EGR) cooling.

The battery cooling plates developed by BorgWarner are extruded aluminum profiles that snake between the rows of cylindrical battery cells, conforming closely to their contours. This design ensures optimal contact with the cell’s surface area for highly effective heat transfer. The plates are interconnected at their ends by a pipe circulating coolant to manage the temperature of the cells.