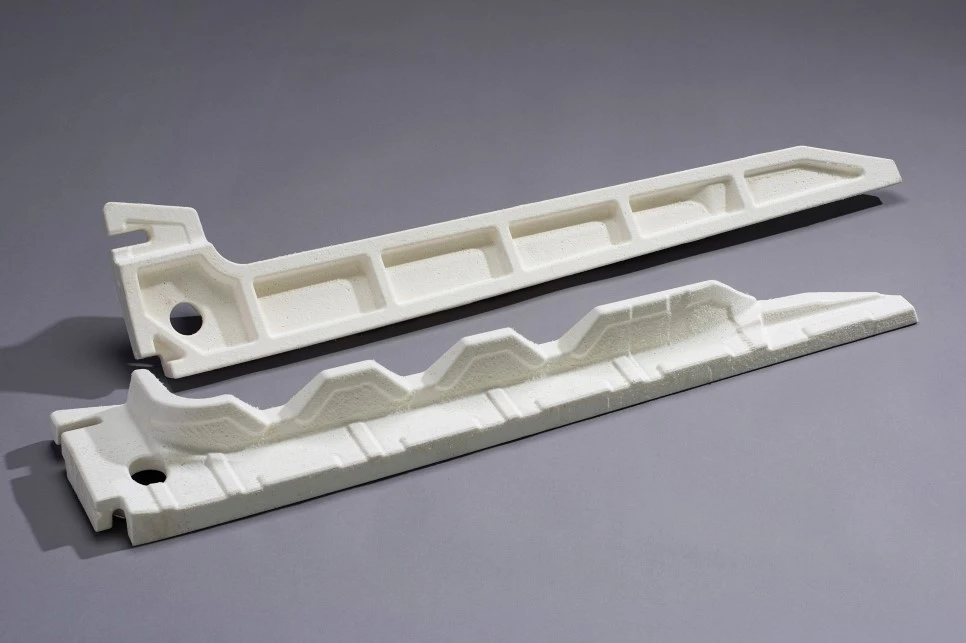

The purpose of an impact absorber is to absorb and distribute the forces arising in a crash and transfer them to the vehicle body. Metal structures, complex and expensive to process, are often used for this. Ultramid® Expand offers several advantages here: Using the polyamide particle foam reduces weight and improves energy absorption in the event of an impact. The production process is also more cost-effective than for metal structures.

Ultramid® Expand is ideal for use in the automotive sector. Ultramid® Expand is a particle foam that withstands the body-in-white painting process, can be used as a reinforcing insert in later closed structures of the car body and can be installed in the body-in-white due to its high temperature resistance. The particle foam fulfils the demanding requirements of the automotive industry for the interior and for long-term use.

Ultramid® Expand particle foam is based on a combination of several polyamide (PA) 6 types. It consists of pre-expanded particles with a defined particle size and density, which can be welded into a 3D component in a molding machine without producing foam waste. The particle foam can be easily processed on existing steam chest molding machines.

Another benefit is that the polyamide particle foam lends itself excellently to overmolding with materials of the same material.