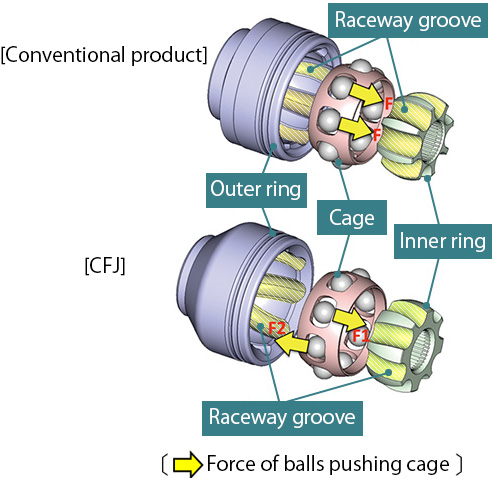

When CVJs transmit torque, balls as the internal component push the cage in one direction, causing friction between components and generating torque loss. Additionally, as operating angle of CVJs increases, the force of balls pushing the cage also increases and it leads increase of torque loss ratio. “CFJ” can reduce torque loss ratio by more than 50% compared to the conventional product by adopting NTN’s proprietary “Spherical Cross Groove Structure” where the adjacent tracks (raceway grooves) are inclined with each other to distribute directions alternately of forces from adjacent balls pushing the cage. In addition, even if the operating angle of CVJ increases, the proprietary structure can significantly suppress the increase in torque loss ratio.

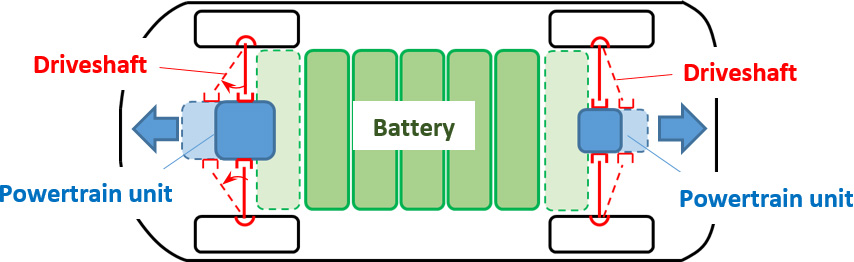

In EV, powertrain unit tends to be mounted at the end of the vehicle considering installation of large-capacity batteries, expansion of the room space, and crash safety, and the mounting angle of driveshaft (CVJ operating angle) tends to become large.

“CFJ” is an optimal product for SUVs that are popular globally in recent years and for EVs/HEVs that are increasingly spread as well. In EVs, operating angle of CVJ is increased, as the powertrain unit tends to be mounted at the end of vehicles, taking into account the installation of large-capacity batteries, expansion of the room space, and crash safety. “CFJ” contributes to improvement in both flexibility of vehicle layout and saving electricity as it demonstrates high-efficiency even at large operating angle. EVs and HEVs are equipped with regeneration brake systems to generate and store electricity by motor when the vehicle slows down. The proprietary structure of “CFJ” also can reduce torque loss ratio when transmitting regeneration torque to opposite direction of usual driving, so it improves regeneration efficiency.