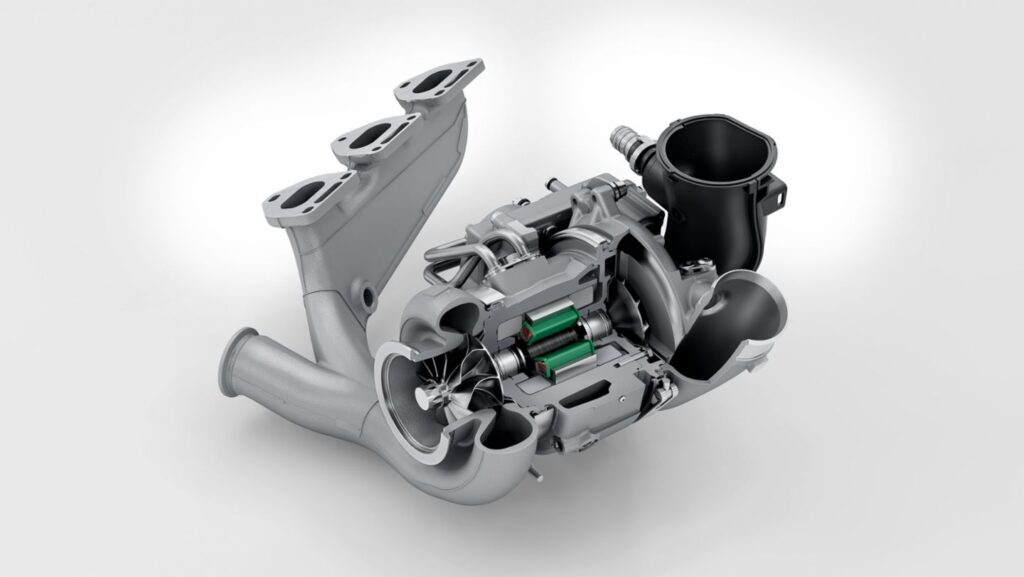

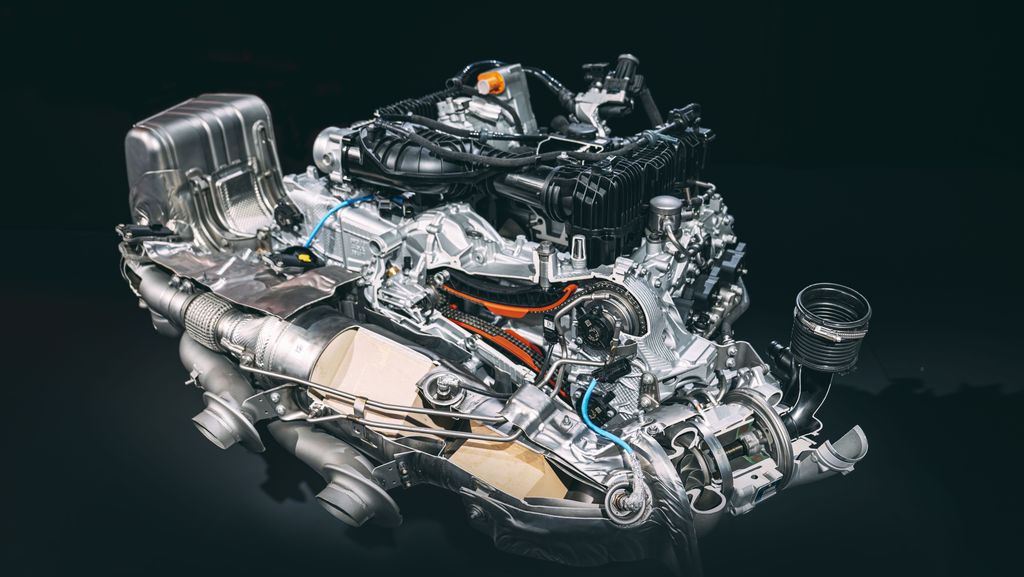

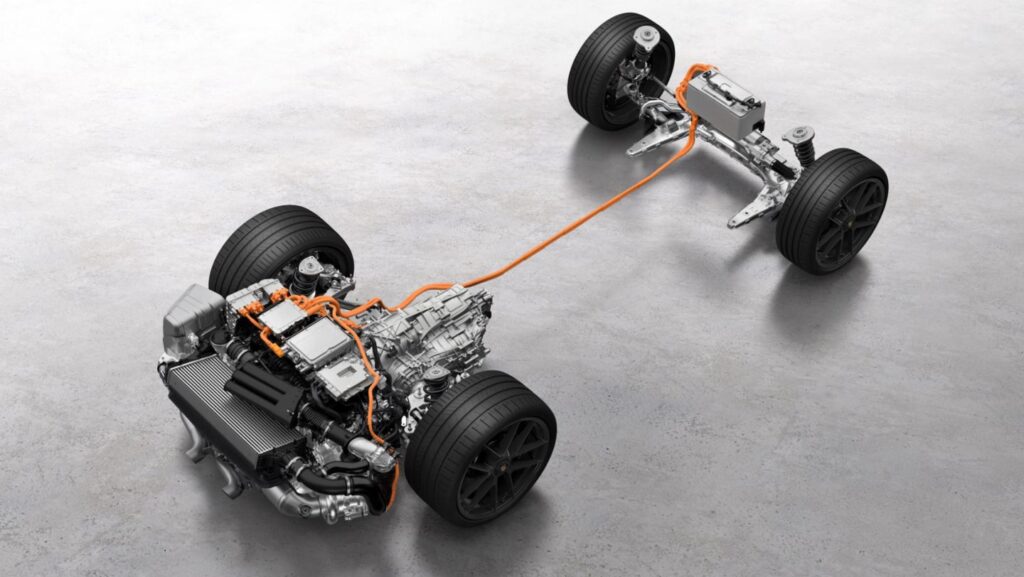

The lightweight and powerful T-Hybrid system has a newly developed electric exhaust gas turbocharger. An integrated electric motor, placed between the compressor and turbine wheel, instantaneously brings the turbocharger up to speed. This immediately builds up boost pressure. The electric motor in the exhaust gas turbocharger also functions as a generator. It generates up to 11 kW (15 PS) of electric power. This energy is extracted from the exhaust gas flow. The wastegate-free electric turbocharger allows the use of only one turbocharger instead of the previous two, which ensures a more dynamic and responsive power delivery.

11 kW recuperation

Electrical motor increases the exhaust acceleration

Faster charger preassure

Possibility for exhaust gas recuperation

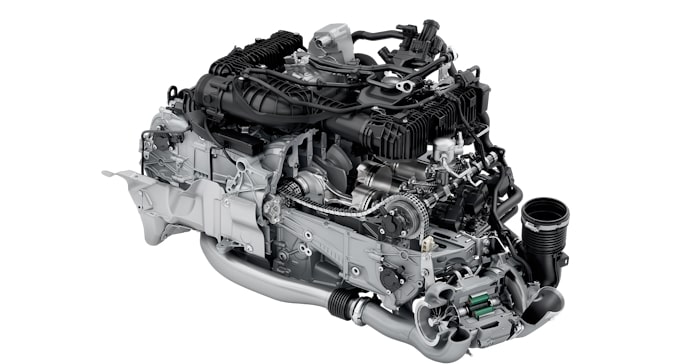

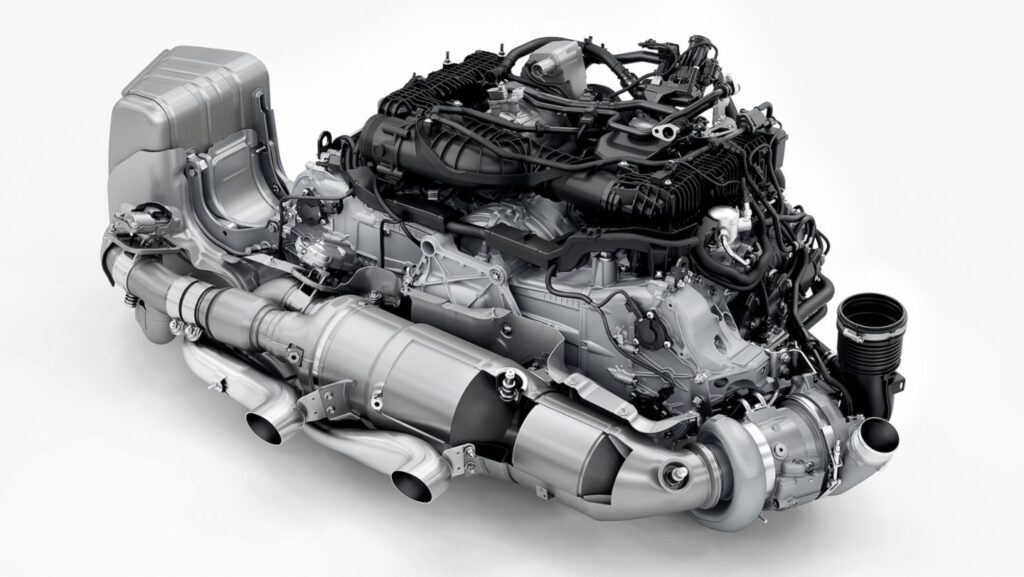

The heart of the T-Hybrid drive is a newly developed 3.6-litre boxer engine. The high-voltage system allows the air-conditioning compressor to be driven electrically and the belt drive to be omitted as a result, making the engine much more compact. This creates space above the power unit for the pulse inverter and DC-DC converter. An enlarged bore of 97 mm and an increased stroke of 81 mm increase the displacement by 0.6 litres compared to its predecessor. The engine has VarioCam camshaft control and a valve control with rocker arms. It maintains the ideal mixture ratio of fuel and air over the entire map (lambda = 1).

Even without electrical assistance, the boxer engine delivers 357 kW (485 PS) and 570 Nm of torque. In total, the system output is 398 kW (541 PS) and 610 Nm. The power increase over its predecessor is 45 kW (61 PS).

The new 3.6-litre T-Hybrid engine is 110 millimeter lower than the current 3.0-litre biturbo engine.

yes. this is the way.

the “road-going” version of the 919 Hybrid.

simply amazing.

two (maybe three) complaints…

the opportunity to have a “hot top deck” allowing:

– centralized location of the e-turbo

– shorter and more compact exhaust manifold

– vent the exhaust, “high side” likened to the 918 Spyder.

– shape the “low deck” intake to allow for a larger under-body venturi

– centralized components now able to design the start of the venturi, at the ‘seat-line’

– venturi now passes entirely through the rear ‘control arm zone’, out through the bumper

– the underbody aero now allows for a cleaner profile, negating the need for a heavy, outboard ‘wing’

– the package has a more central center of gravity and better aerodynamic capabilty.

and lastly. utilize liquid-to-air intercooler and route cooling lines of the heat exchanger to the front…

based on that imagine, it looks like the air-to-air intercooler is directly above the catalytic converters.

so i can only surmise that theres a bunch of extra heat shield and thermal isolation blankets there.

thus, the air flow to the intercooler flows how? a bunch of ducting in the bumper?

i digress.

kudos to the team at porsche. this drivetrain setup is going to be stellar.