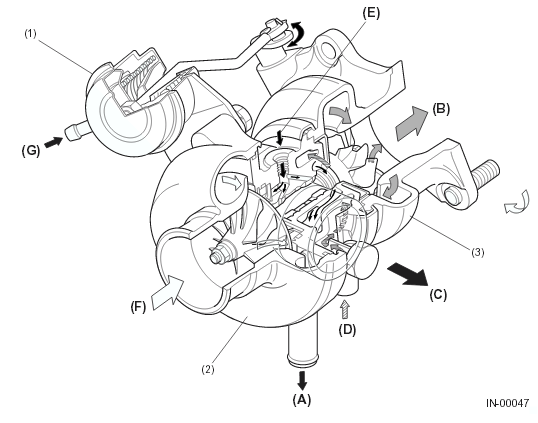

(A) Lubricating oil outlet (E) Lubricating oil inlet

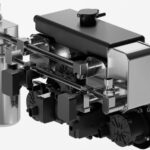

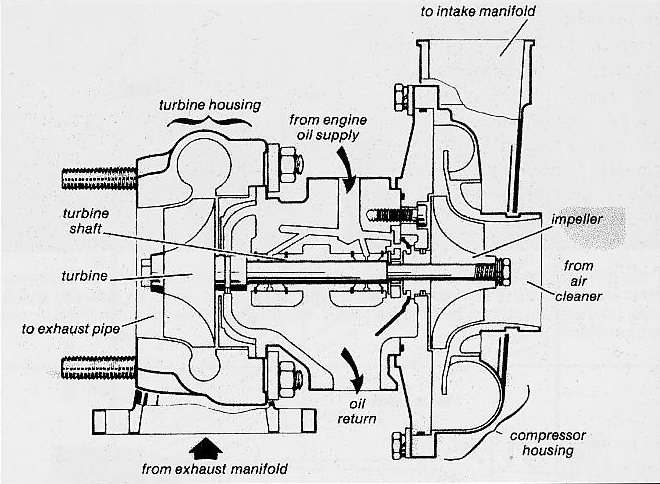

A turbo-supercharger receives its oil supply from the engine, although there is at least one unit on the market with a self-contained lubrication system.

In this unit the main bearings are located in the cold-side compressor housing rather than between the compressor and turbine housings. A cavity is built into the front portion of the compressor housing in which specially formulated high-speed bearing oil resides. This oil is transferred to the ceramic ball bearings via a pair of wicks through which a mist of oil is drawn; as the bearings are not flooded in lubricant, drag is reduced, and due to the bearings’ location, lubricant temperatures are also kept low.

However, in most conventional turbos the bearings are located between the hot and cold sides of the turbo, and are subject to much greater heat transfer from the exhaust gases, so a constant flow of oil is needed. This flow lubricates the bearing and contributes to cooling. Many modern turbos often feature additional water cooling, but some still rely solely on the oil. Regarding the plumbing of turbos, it is widely known that the bore of the exit pipework for the turbo oil supply must be far larger than that of the inlet, to accommodate any aerated oil. Similarly, unless a scavenge pump is fitted, the oil exit must be above the level of the main engine sump to allow the lubricant to drain.