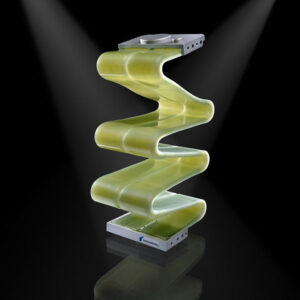

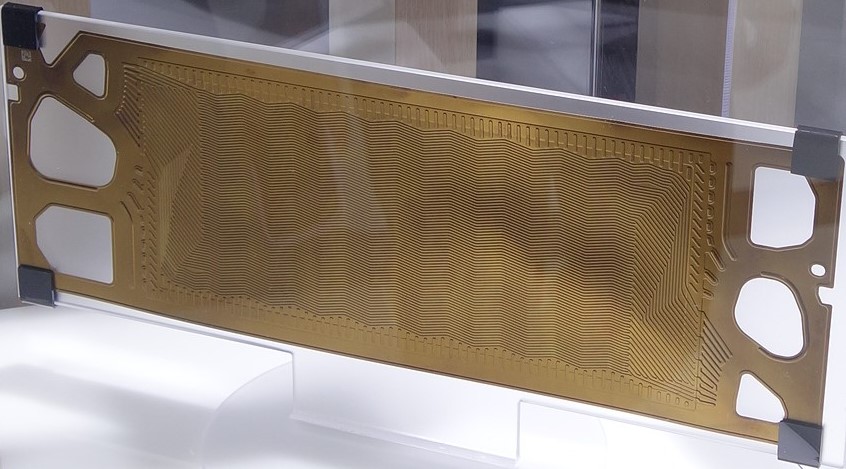

Toyota Boshoku has developed a new method of stamping separators for fuel cell stacks using the company’s proprietary precision stamping and molding technologies. This enables high-speed production by vastly shortening the conventional multi-stage process of forming the channels used for the hydrogen and coolant flowing through the separators.

Flow hydrogen evenly in fuel cell

Collect generated electricity

Precise stamping available for thinner plate

More complexed flow paths can be precisely stamped

In addition, the design also utilizes an ion exchanger, improving adsorption of ions in the cell fuel cell stack coolant by 130%.