Xylon just revealed XYLON QUATTRO®, the company’s 4th generation data logging and HIL system for development, testing and validation of autonomous driving (AD) and vision-based advanced driver assistance systems (ADAS). With its future-proof and unprecedented feature set, the new XYLON QUATTRO is ready to support automotive developments up to the L5 autonomy. It greatly complements the existing third-generation logiRECORDER data logger that will be actively maintained and upgraded for use in performance and cost-optimized automotive developments.

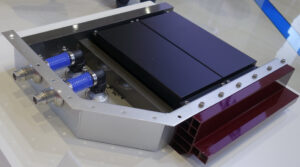

XYLON QUATTRO offers 128 Gbps of data logging and playback bandwidth, up to 128 TB of internal data storage and industry’s best automotive interfacing. It enables direct connections of up to sixteen (16) video cameras, with resolutions up to 32 MP, via current LVDS interfaces, such as GMSL2 from Analog Devices or FPD-Link III from Texas Instruments. Xylon is already working on support for next-generation LVDS interfaces. XYLON QUATTRO is backwards compatible with the existing logiRECORDER video I/O modules, which assures an immediate support for different video interfaces.

High-end LIDAR and RADAR sensors, as well as many other automotive systems can be directly interconnected via up to sixteen (16) 10M/100M/1G/2.5G/10G Ethernet (BASE-T) and Automotive Ethernet (BASE-T1) channels. Four-channel Ethernet modules can be configured into the fastest, HW-based two-channel TAP configuration, thus eliminating the need for expensive external Ethernet switches.

XYLON QUATTRO can directly interface, without external converter boxes, more than twenty (20) low and mid speed automotive interfaces, including different versions of CAN, LIN, UART and FlexRay networks. It complements the device’s high-speed data logging and playback to enable a complete collection of centrally timestamped vehicle data.

The key XYLON QUATTRO differentiator is Xylon’s unique programmable hardware engine configurable at the FPGA chip level. Custom designed hardware enables data processing out of reach to software or common hardware-based processing engines, such as real-time insertion of a “live” video camera’s metadata into synthetically generated camera data for HIL testing of an ECU under test that runs the production firmware mode.

To add even more flexibility, Xylon has expanded the HW engine with a complete x86-based PC to offer new possibilities in data logging and HIL playback, AI triggering and filtering, automated scripted testing, etc. The company has heavily invested into an open software architecture to enable user customizations and modularity, e.g. high-speed sensors emulation and support for existing and emerging protocols and services management (SOME/IP, DoIP, DDS…).

In HIL setups, Xylon systems work as smart I/O boxes that convert synthetic data from multiple and heterogeneous vehicle sensors modeled within the simulation platform into physical automotive interfaces connected to real ECU and domain controllers under test. This real-time interface between the synthetic and real world works in both directions and enables full virtual test drives. While the third generation data logger has a single 10 GbE HIL port, the new XYLON QUATTRO integrates two (2) 100 GbE HIL ports to enable the most complex simulations like ECU perception algorithms checkup based on simulated high-resolution camera and LIDAR inputs.