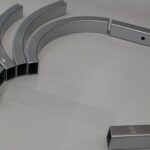

Vibracoustic presents innovative solutions for electric motors of battery electric vehicles (BEV). The compact polymer beam structure and the integrated thermoplastic elastomer bushings allow full integration, weight reduction and simplification of assembly while also meeting requirements for stiffness and isolation performance. The solutions are offered with different levels of integration, ranging from bushings to a more sophisticated beam mount.

Focused on meeting new OEM requirements for EDU (electric drive unit) mounting, Vibracoustic’s engineers have developed a modular motor mount bracket and a highly-integrated beam mounting structure for BEVs. The motor mount bracket is a modular and lightweight solution that uses a thermoplastic elastomer (TPE) bushing with double isolation for improved efficiency, with the entire part acting as a damper. This mount offers cost savings through dual injection production technique and can be tailored to the desired stiffness by changing the part’s geometry. The use of TPE in NVH applications is an innovative alternative to natural rubber.

The second technology is a patented, lightweight, compact composite or polymer ‘beam’ structure. This integrated solution uses the same TPE bushings and double isolation technology while further optimizing NVH management. It provides significant weight savings of up to 25%, is smaller than comparable alternatives and simplifies assembly which leads to reduced cost. The engineering team was also able to integrate a TPE damper mass into the beam’s construction, further optimizing NVH without compromising packaging.