Toray Industries, Inc., announced that it has developed a rapid integrated molding technology for carbon fiber reinforced plastic (CFRP) mobility components. This material sandwiches a light, porous carbon fiber-reinforced foam (CFRF) core with a thermosetting prepreg skin offering outstanding mechanical properties.

This new technology makes it possible to mold such CFRP mobility components as a car roof 10 times faster than a conventional autoclave molding setup. Such offerings can be just half the weight of steel counterparts. Toray will keep pursuing R&D to accelerate the application of this technology to electrified vehicle parts, for which lightness and fast production are vital.

CFRP members typically sandwich urethane foam cores with thermosetting prepreg skins. Common applications for these light and rigid structures are large panels for aircraft, automobiles, ships, and infrastructure. Some have pushed for shorter manufacturing times to optimally bond the core after shaping it to the skin.

Toray’s new rapid integrated molding technology makes it possible to fabricate large panels in a single press shot. That is because this approach simultaneously shapes, thermosets and molds, and bonds the core CFRF and thermosetting prepreg skin in the same mold.

Synchronizing CFRF’s expansion with the prepreg’s curing timing is significantly faster than with conventional processes. The prepreg thermosetting resin penetrates the porous CFRF to bond the skin and core materials without using adhesives, for a highly reliable bonding structure. Toray’s technology paves the way to quickly producing large CFRP components.

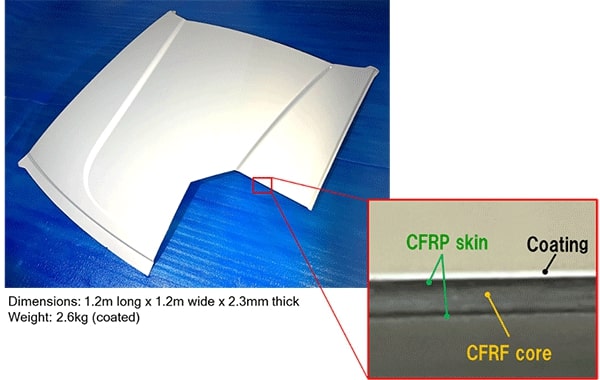

CFRF offers significantly better strength, elastic modulus, and impact resistance than conventional core materials. Its low specific gravity range of 0.2 to 0.4 can enhance performance and lighten sandwich structures. Toray demonstrated its concept by using a pressing machine to create a large automobile roof panel (1.2m long x 1.2m wide x 2.3mm thick) in just five minutes. This was 10-fold faster than the conventional approach. The company assessed rigidity tests, coatability, sound insulation properties, and other practical aspects for automobile production. In vital drop-weight impact tests, Toray confirmed that the skin core interface did not delaminate and that impact absorption is excellent.