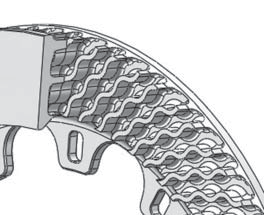

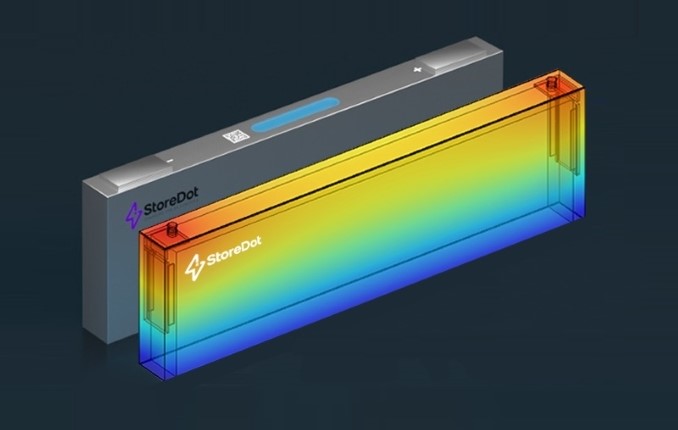

Prismatic cells, which are rectangular and stacked in layers, now represent the form factor of choice for a growing number of electric vehicle manufacturers. These types of cells offer added mechanical protection and performance advantages, while the flat surface simplifies the integration into electric vehicles with better thermal management and safety considerations – thus reducing pack assembly cost and complexity.

However, the transition from pouch to prismatic cells, and moreover, the integration of silicon-based chemistry with Extreme Fast Charging (XFC) capability in prismatic packaging, introduce several engineering challenges and manufacturing complexities. The solution, achieved by StoreDot’s global teams, is based on careful design of the stack thickness, formation currents and pressure regimes as well as managing the associated swelling of silicon-dominant anode technology and high currents in a prismatic hard case enclosure.

By overcoming these hurdles, StoreDot has shown its XFC technology is factor-agnostic and can be adapted to different cell form factors needed by automakers. The company will continue to optimize the design to achieve up to 170Ah of cell capacity and over 700 Wh/L volumetric energy density.

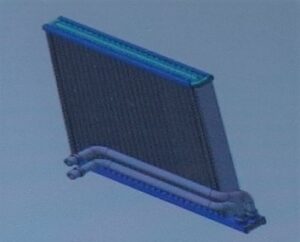

The announcement follows StoreDot’s news earlier this year that it had unveiled a breakthrough XFC concept for taking extreme fast charging from the cell to the vehicle level with its new I-BEAM XFC™ design, an innovative cell-to-pack concept that will also accelerate XFC integration into EVs.

StoreDot remains on track with production-readiness of XFC cells that can deliver 100 miles charged in 5 minutes this year, 100 miles charged in 4 minutes in 2026 and 100 miles charged in 3 minutes by 2028.