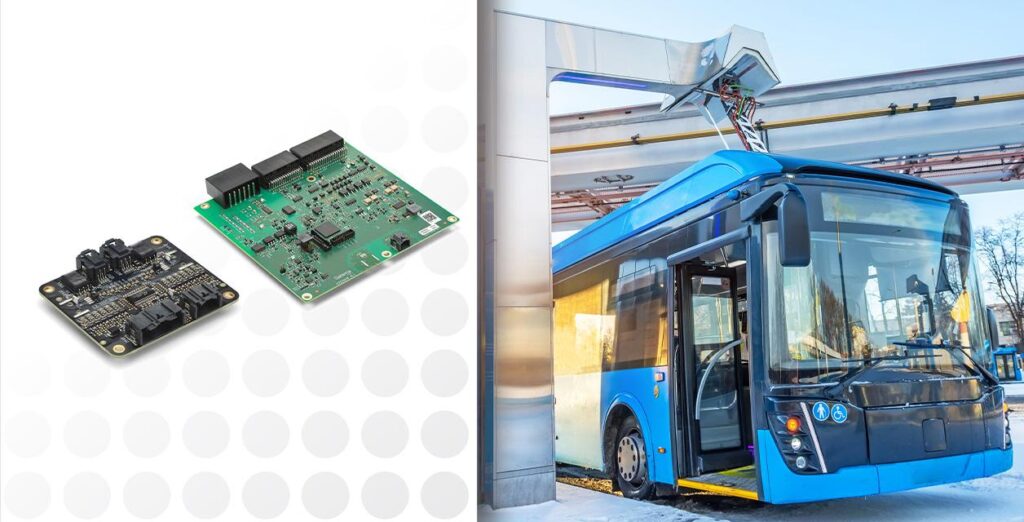

The Lithium Balance n3-BMS is ideal for applications with power up to 1000 volts/2000 amps, especially for battery makers and manufacturers of electric trucks, buses, and other heavy commercial vehicles. The demand for ISO 26262 certified components is on the rise as battery packers and electric commercial vehicle OEMs prioritize functional safety in their platforms while striving for faster time-to-market. However, the ISO 26262 certification process is complex, costly and can take years to complete. An off-the-shelf, Automotive Safety Integrity Level (ASIL C) certified solution like the Lithium Balance n3-BMS can reduce the development time and associated costs.

The unique layered software structure of the n3-BMS provides customers with the option to customize the battery management system with their own code and algorithms without impacting the ASIL C certification. The BMS software architecture consists of a “Base Software Layer” (BSW) and an “External Software Layer” (ESW) which are connected by an open API link layer. Since all the safety-critical functionalities of the BMS are in the BSW layer of the software, developers are free to implement their own software code and algorithms in the ESW without any risk to the ISO 26262 certification of the system.

The n-BMS’ MCU is fully compatible with the n3-BMS’ CMUs, so it is easy to upgrade from n-BMS to n3-BMS with the replacement of a single PCB board in a battery system of any size. For developers currently working on next generation, heavy electric vehicles that expect the need for an ISO 26262 certified system in the future, this provides a convenient and cost-effective pathway to achieve an ASIL C certified BMS with a simple upgrade (available early 2023).