To achieve greater synergies and even shorter development times for its custom solutions, Schaeffler established a new Bearings business division within its Automotive Technologies division at the start of this year.

Schaeffler’s TriFinity product is a triple-row wheel bearing designed for use in electrified powertrains. This innovative ball bearing design provides an alternative to preloaded tapered roller bearing units. Switching from tapered rollers to balls leads to significant improvements in frictional torque and rigidity, resulting in a 0.7 percent reduction in electricity consumption per vehicle in FTP75 test cycles. The combination of the TriFinity with Schaeffler’s face spline technology allows downsizing solutions in the form of wheel bearing units with smaller diameters, and hence reduced bearing and seal friction, optimized bearing weight, and a smaller carbon footprint. For the same dimensions, the clearance-free face spline technology reduces bearing weight while enabling the component to transmit up to 50 percent more drive torque. It also makes the bearing easier to mount and reduces noise emissions in electric vehicles.

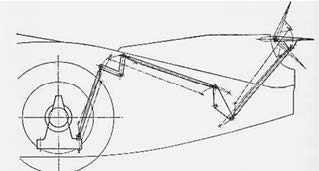

Schaeffler’s new high-efficiency ball bearing with centrifugal disc combines the benefits of both open-bearing and sealed-bearing designs. With 0.3 Nm less friction and CO2 emission reductions of about 0.1/km per bearing, the high-efficiency ball bearing with centrifugal disc is a smart yet simple solution that has a major impact on overall performance. It has ten times the service life of an open bearing and represents a significant reduction in costs.