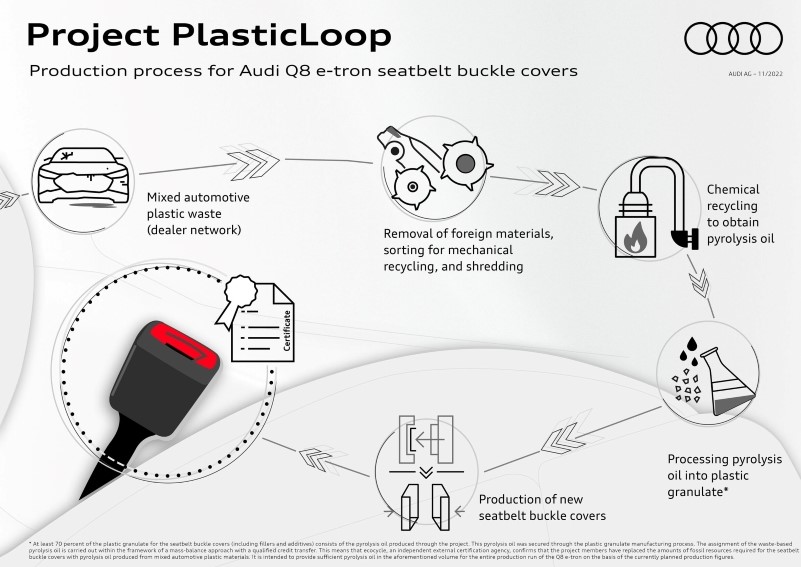

Audi has launched cutting-edge plastic covers for seatbelt buckles in its Q8 e-tron models; the casings are partially manufactured from mixed automobile plastic waste using a chemical recycling process. It is the first time the company is installing safety components made in this way, and in conjunction with the PlasticLoop project, has established an innovative process with plastics manufacturer LyondellBasell, based on the findings from a pilot project.

How plastic components that are beyond repair are first stripped from customer vehicles, freed of foreign materials such as metal clips, before being broken down into smaller pieces, and processed into pyrolysis oil by means of chemical recycling. This oil is then used as a raw material for the manufacture of new plastics, harnessing a mass balance approach. The plastic granulate thereby obtained, is utilized in the production of Q8 e-tron seatbelt buckle covers.

Through this process, the automotive manufacturer together with the other project participants have managed to recover a flow of materials which are usually only suitable for energy recovery. This operation will allow Audi to use fossil raw materials for longer and reduce its purchasing of additional primary materials for the Q8 e-tron accordingly. Materials produced from the pyrolysis oil are of the same high standard as newly manufactured goods and offer identical technical characteristics.