PLS Programmierbare Logik & Systeme now supports the latest automotive MCUs from STMicroelectronics’ Stellar E family.

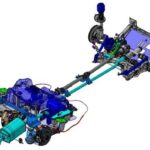

Optimized for software-defined electric vehicles and with its functions for fast execution of control loops, the Stellar E family is primarily intended for use in power electronics applications such as on-board chargers or DC/DC converters. It is based on two Arm® Cortex®-M7 cores, each clocked at 300 MHz, which can be operated either in a dual-core configuration or, for the highest demands on functional security, as a single core with lockstep. For applications with increased security requirements, the integrated Hardware Security Module (HSM) offers, among other things, functions for accelerating cryptographic tasks. The MCUs are equipped with up to 2 MB on-chip flash. Split into two banks the code Flash allows software updates OTA.

PLS’ UDE 2022 enables Stellar E MCU users to perform true multi-core debugging for both Cortex®-M7 application cores and optionally for the HSM in a single debug session and within a common debugger instance. The UDE Multi-Core Run Control ensures full synchronization of all cores during debugging at all times. Depending on the use case, the cores can also be started and stopped individually. Multi-core breakpoints, which can be used in shared code, simplify the debugging of complex applications. Such a breakpoint is always effective and completely independent of which core is currently executing the respective code. To realize these functions, the UDE 2022 utilizes the Arm® CoreSight™-600 debug and trace system implemented in the Stellar E MCUs. This allows the user to additionally use very flexible triggers and hardware breakpoints.

The UAD2pro, UAD2next and UAD3+ devices from PLS’ Universal Access Device family, together with the corresponding target adapter, ensure fast and reliable communication with the Stellar E MCUs via JTAG or Serial Wire Debug (SWD). For electrically demanding development environments, galvanically isolated adapters are also optionally available, enabling potential isolation up to 1,000 volts.

For non-invasive debugging and more extensive runtime analyses, UDE uses recorded trace data from the Stellar E MCUs. Among other things, function or task executions over the time are visualized or profiling can be used to uncover optimization potential. The recording of large amounts of trace data can be done either with in the UAD2next or in the UAD3+. For this purpose, 512 MB of trace memory is available in the UAD2next and up to 4 GB in the UAD3+. The fast download of the trace data off chip towards the UDE is done via the parallel trace interface of the Stellar E devices.