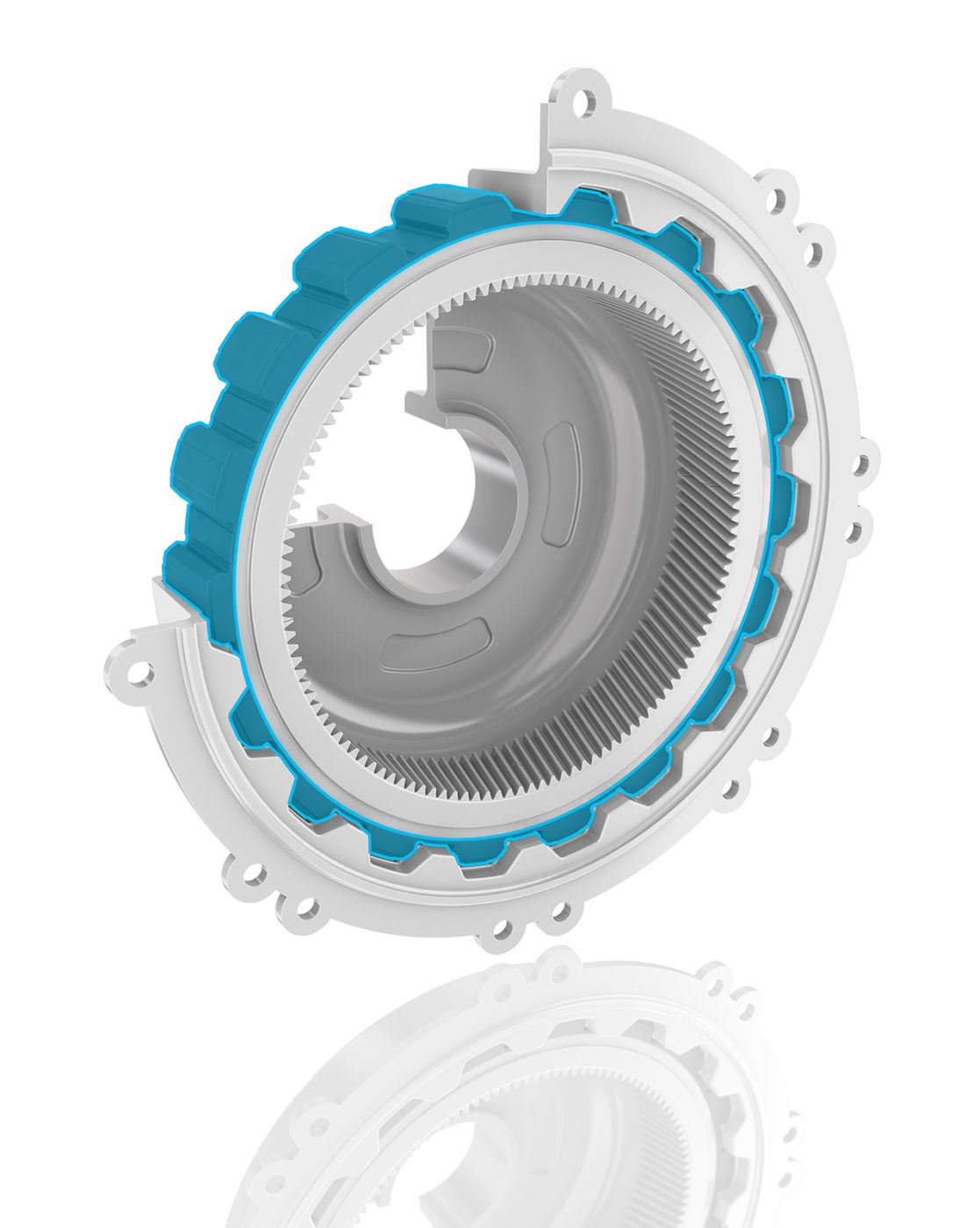

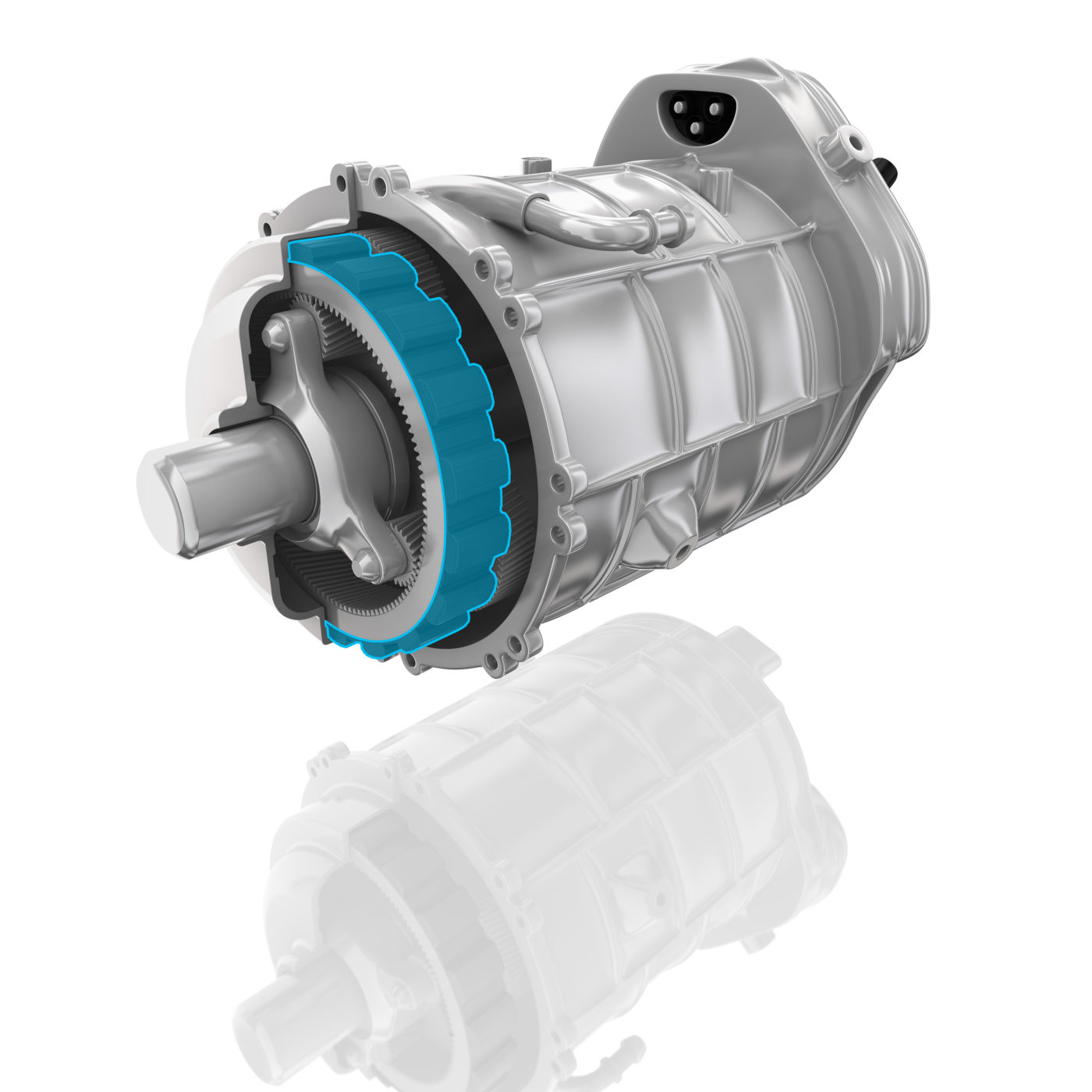

Vibracoustic has developed an elastic ring gear to help mitigate electric drive unit (EDU) excitations in electric vehicles (EVs) planetary gearboxes.

While most manufacturers have effectively decoupled and isolated their EDUs, there are still excitations causing noticeable NVH issues. Common among current EV production models are high-frequency excitations like torque ripple, caused by e-motors and vibrations that are transmitted into the gearbox housing.

Vibracoustic’s engineering team developed a solution to these challenges for planetary gearboxes by adding a vibration isolation between the housing and the ring gear. Through extensive simulation and material evaluation, they designed a tunable rubber ring gear that offers multi-directional decoupling (radial, axial and torsional) to significantly reduce the transmission of vibrations. Extensive finite element analysis (FEA) also concluded that Vibracoustic’s elastic ring gear delivers a wide range of sound-pressure reductions. The elastic ring gear therewith offers high frequency NVH optimization for electric drive systems with planetary gearboxes and can even make addition acoustic encapsulations obsolete due to its wide frequency working range.