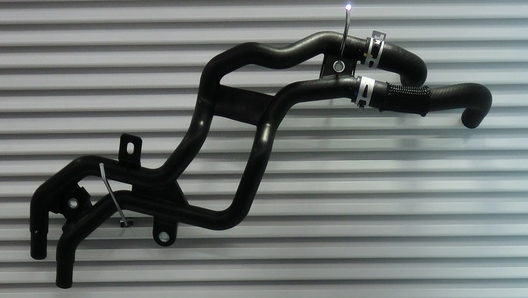

The water-assisted injection forming method is a production technology to mold plastic pipes with three-dimensional curves while squirting water to produce hollows through the pipes.

The development reduces weight by about 40% compared to conventional water pipes consisting mainly of iron or stainless steel.

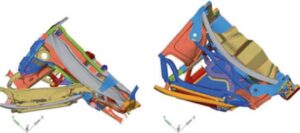

Plastic pipes with these three-dimensional curves can help downsize the engine room.

Plastic pipes having these necessary components as a unified part help cut production costs.