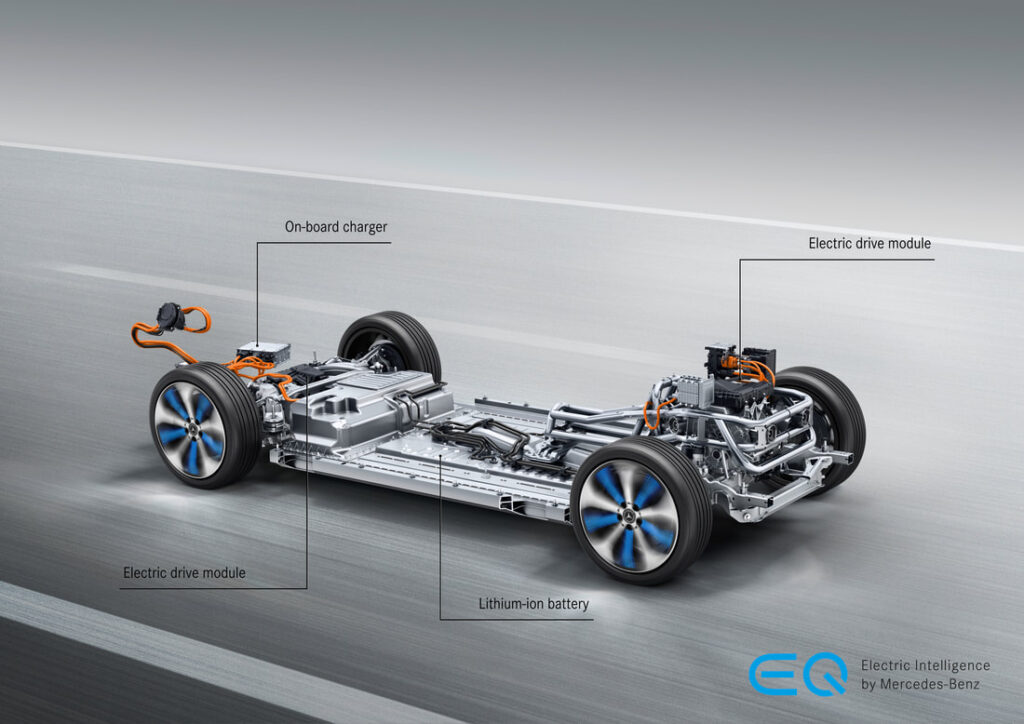

The centerpiece of the Mercedes-Benz EQC is the lithium-ion battery, which serves as the energy source for the two electric motors. It is manufactured in-house at Deutsche ACCUMOTIVE in Kamenz.

The battery is comprised of 384 cells arranged in the vehicle floor between the front and rear axle. It is divided up into two modules with 48 cells each and four modules with 72 cells each. The powerful high-voltage battery with a voltage of about 350 V has a usable energy content of around 80 kWh. Depending on the cycle, this makes a range of more than 450 km possible (measured in NEDC). The safety of the batteries was also affirmed in different crash tests. In addition, the low and central arrangement improves the handling of the EQC.

Battery weight: 650 kg

Depending on the SoC (status of charge), the EQC can be charged with a maximum output of up to 110 kW at an appropriate charging station. In around 40 minutes, the battery can be charged from 10 – 80 percent SoC (provisional data).

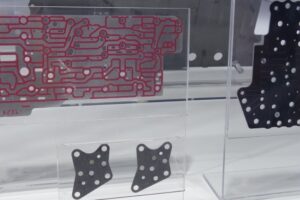

Mechanical protection of the battery: the high-safety design begins with the installation position of the high-voltage battery beneath the vehicle floor. The energy storage unit is surrounded by a stable frame that can absorb energy. Deformation elements are installed between the frame and the battery, and these are able to absorb additional forces in the event of a severe side impact. A battery guard in the front area of the battery is able to prevent the energy storage unit from being pierced by foreign objects.