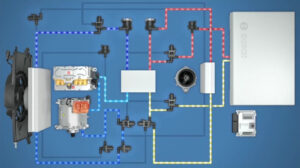

Special attention was also taken over the correct management of heat flows.

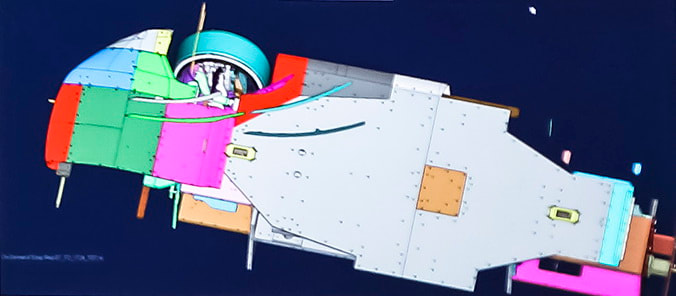

Its front incorporates an elaborate system of vortex generators, rendered even more effective by the distinctive hump shape of the floor, which gradually rises in the centre, in the area level with the wheels, to increase the air flow to these devices, before reconnecting to the chassis bed.

The venting channel in the area behind the front wheel starts near the point where the hump reaches its greatest extent and continues right along the side, generating a considerable vertical load in line with the front axle due to the expulsion of the air flowing from the bottom and the wheel arch.

To conclude, the rear part of the floor of the car includes a large diffuser, with channels of different depths and optimised vertical spoilers that exploit the pressure differences between the various sections to generate vortices and energise the air flow.

Computational Fluid Dynamics (CFD)

Used in all development phases, it allows testing of multiple geometrical configurations in short times, monitoring a large number of physical parameters through complete analysis of the flow field.

Full size wind tunnel (FCA Orbassano)

Used in the detailed design phase, it reproduces the motion of the real air flow around the vehicle, enabling optimisation of even small-size components.

Scale wind tunnel (Dallara)

Used in the preliminary design phase, it supplies initial experimental feedback and guides development along the correct lines through in-depth analysis of aerodynamics in various vehicle configurations.