Marelli presents its first hydrogen fuel system, including specific injectors with patented design and an advanced Engine Control Unit. Based on the company’s expertise in the high-pressure direct injection technology, the new Marelli’s fuel system meets the strict requirements of these engines, ensuring precision, efficiency, performance, easy integration and complexity reduction.

As hydrogen is a very light and reactive gas, a very precise fuel injection inside the combustion chamber is required, together with specific solutions to avoid pre-ignitions and backfire. It also needs a higher compression ratio than common gasoline engines to exploit the fuel efficiently. This makes the direct injection system a key enabler for this technology.

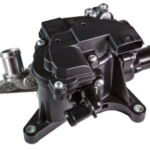

This allowed the company to develop reliable and low-noise direct injectors aimed for hydrogen, with the same dimensions as those used for traditional fuels, making it easier for carmakers to integrate them into existing platforms. Moreover, these injectors feature a double actuation, a specific magnetic circuit to control the speed of the needle and a high static flow that can meet the requirements of a variety of different vehicles. The patented design also allows to overcome uncontrolled hits between the injector’s dynamic components, to reduce performance drifts. Finally, the use of a standard command control contributes to reducing system costs and complexity.

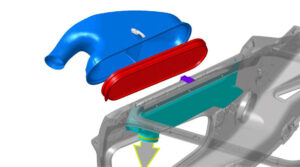

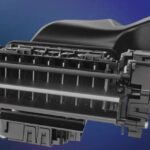

The fuel system also includes a pressure reducer with an integrated regulator, to reduce hydrogen pressure to the injection’s working pressure, and a specific manifold, tested for the most severe automotive applications. The whole functioning is controlled by an advanced Engine Control Unit, featuring software algorithms and specific strategies developed in-house by Marelli to manage the more complex hydrogen-based system.