Measuring micro-vibrations is necessary in many engineering applications: accurate GPS data depends on stable space crafts and satellites, while automobile developers need NVH testing (noise, vibration and harshness) to optimize driving comfort, vehicle performance, durability and reliability. Because micro-vibrations occur in the micro-g range, a highly sensitive measuring chain with very low noise is required for such applications.

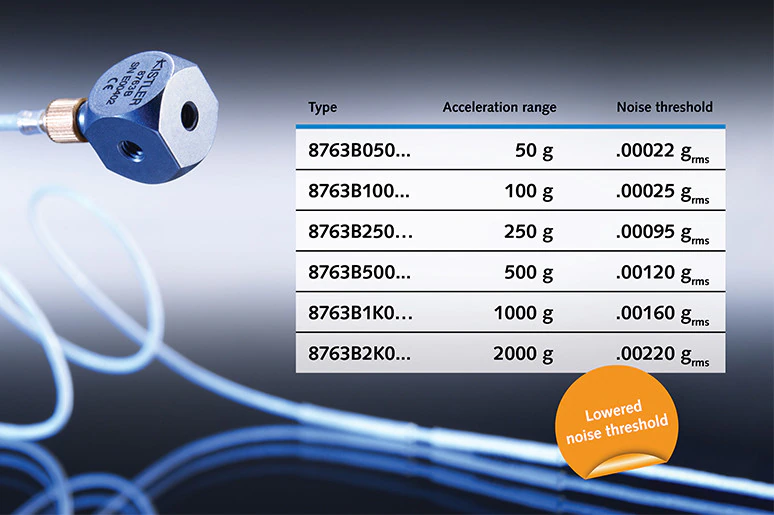

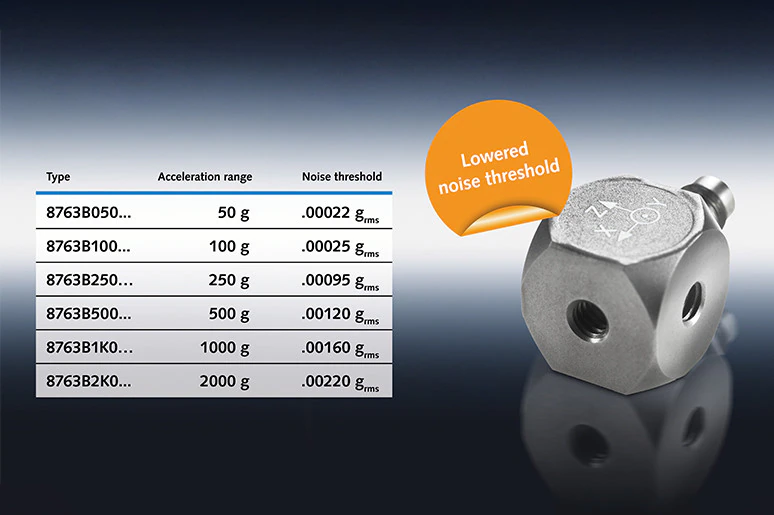

The IEPE (Integrated Electronics Piezoelectric) triaxial accelerometer 8763B is the most common Kistler sensor used for these measurements and permits vibration monitoring in three mutually perpendicular axes. The measuring threshold determines the smallest possible level of vibrations that can be reliably picked up by the sensor. In 2021, Kistler already improved the noise threshold for the 50-g range. The 8763B now features a significantly lower noise threshold for all its ranges: a 58-percent lower noise threshold for its 100-g range, 37 percent for the 250-g range, 52 percent for the 500-g range, 54 percent for the 1000-g range and 51 percent for the sensor’s highest range of 2000 g. With these improvements sensor 8763B becomes even more suitable for common applications, like modal analysis, frequency response measurement and e-motor testing.

The 8763B sensors provide a wide frequency response in each orthogonal axis, making it well-suited for dynamic vibration measurements, especially on lightweight structures. Other features include the sensors’ lightweight hermetic titanium housing and high immunity to base strain thanks to shear element technology. An integral silicone cable variant is available for underwater vibration testing at up to 10 bars. Sensors of the 8763B family can be installed on test objects by either adhesive mounting or flexible studs thanks to three 5-40 threaded holes, making it possible to fully utilize each mounting side of the cube design, ensuring reliable mounting for the calibration of each axis.