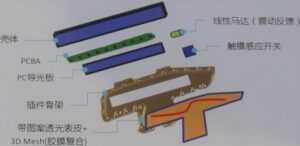

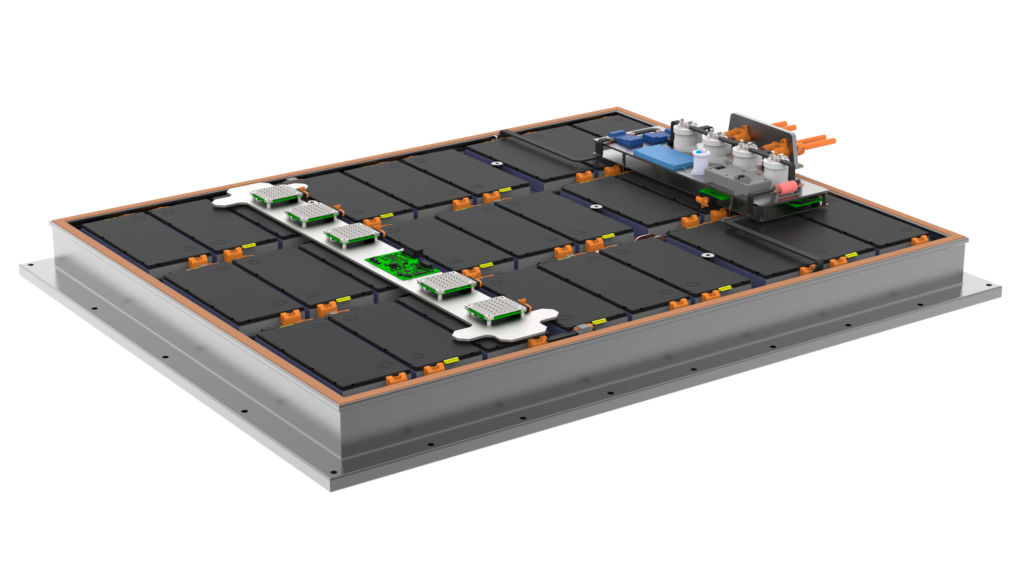

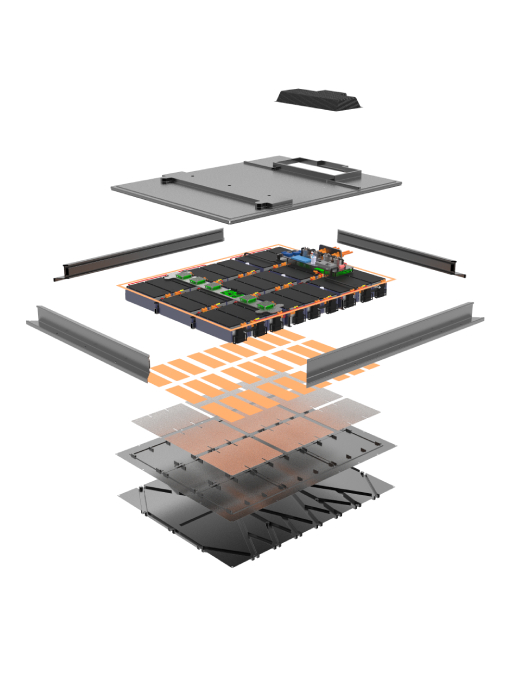

The core element of IAV’s concept is a new type of module and battery housing design. In the future, these would be made of more recyclable materials and, thanks to innovative joining techniques, can be joined and separated more easily. This also reduces the cost of producing and recycling the peripheral elements by up to 50 percent compared to conventional battery systems.

The IAV battery concept replaces aluminum with steel. The material can be separated in the recycling process more easily and with less energy than aluminum. Thanks to consistent lightweight design, the use of steel increases the weight of the battery by only around one to one-and-a-half percent and is therefore negligible in terms of driving performance and range. Instead of multiple screw solutions, bonding and welding seams, IAV engineers have introduced new joining techniques. Wherever possible, click and plug-in connections are used. This means that the number of bolted connections can be reduced by two-thirds, and bonding and welding can also be significantly cut back.