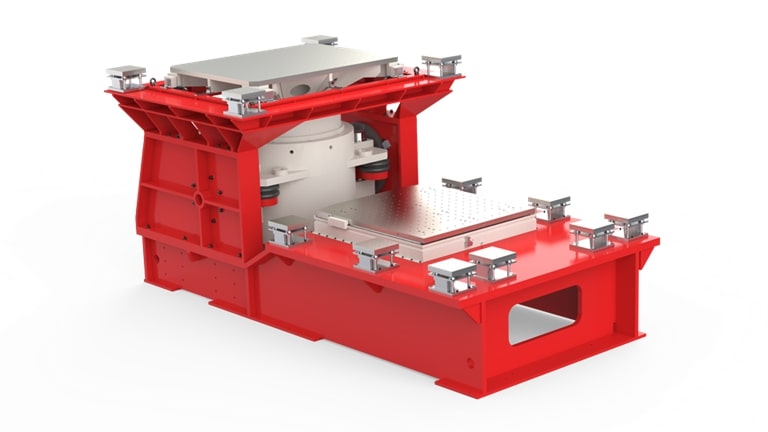

To help industries involved in vehicle and battery manufacturing optimise their designs – and speed up time-to-market – HBK has created the V9940 shaker platform.

A water-cooled electrodynamic shaker with a Sine force rating of 300 kN, used for vibration and mechanical shock testing of extra-large payloads of up to 5000 kg (11,000 lb) as standard, such as the batteries of electric and hybrid vehicles and e-axles and e-drivetrains.

Designed primarily for testing EV battery systems during prototype development to validate product release to series production, the V9940 shaker system can also be used for end-of-line sample testing to validate manufacturing process parameters and ensure consistency of quality, making it ideal for vehicle and battery manufacturers, independent Test Houses and Systems Integrators.

The HBK Project Sales Office manages integration of the V9940 Shaker platform with Climatic Chambers from leading manufacturers, so that reliable and meaningful data about the Device Under Test (DUT) can be collected and analyzed. Effective interfaces between the Shaker and Climatic Chamber ensure that the test environment accurately simulates real-world environmental conditions during battery tests, while providing important safety functions such as isolation and containment in case of thermal runaway.