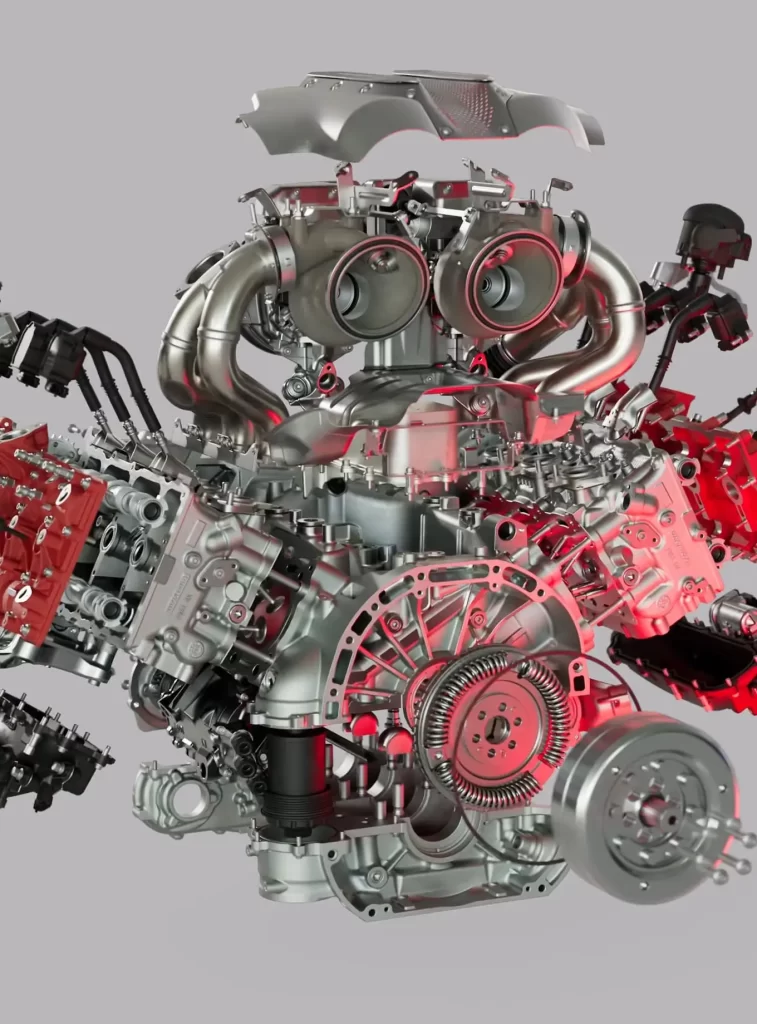

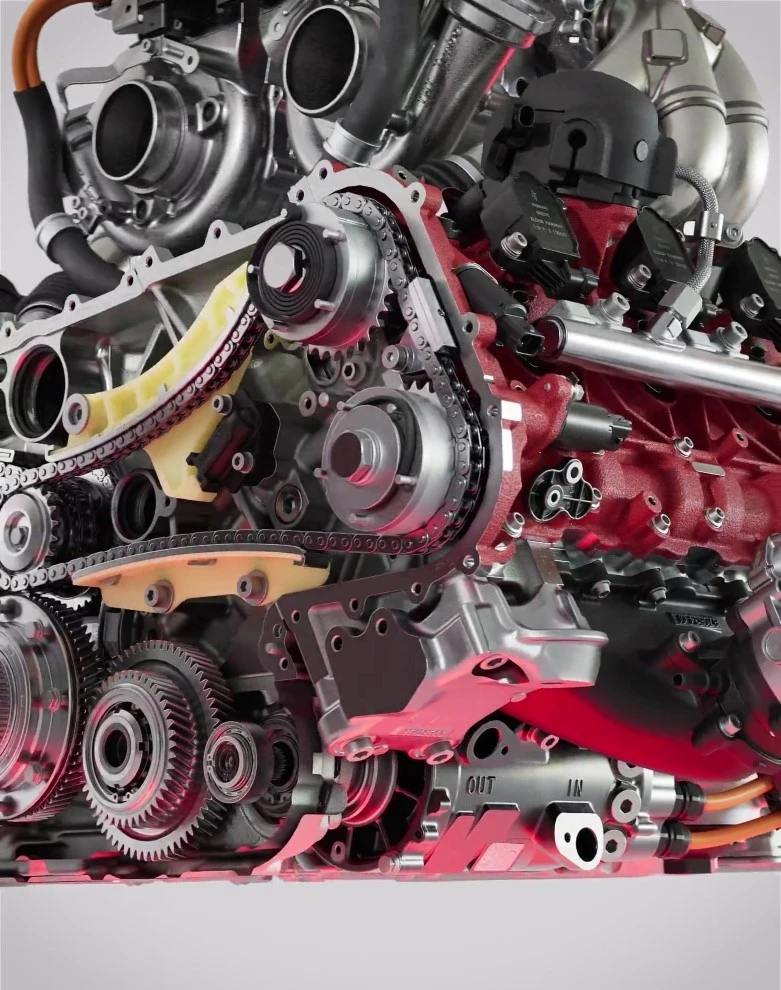

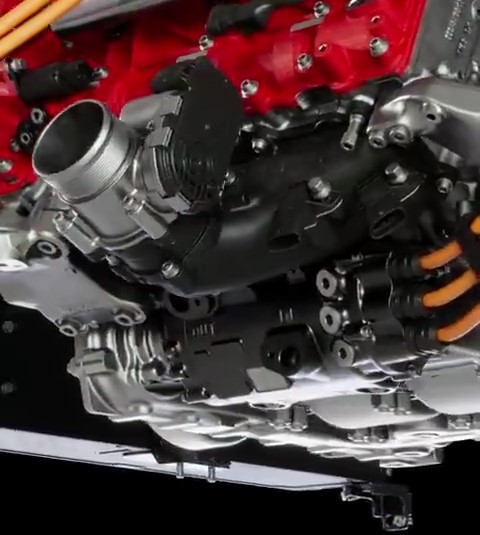

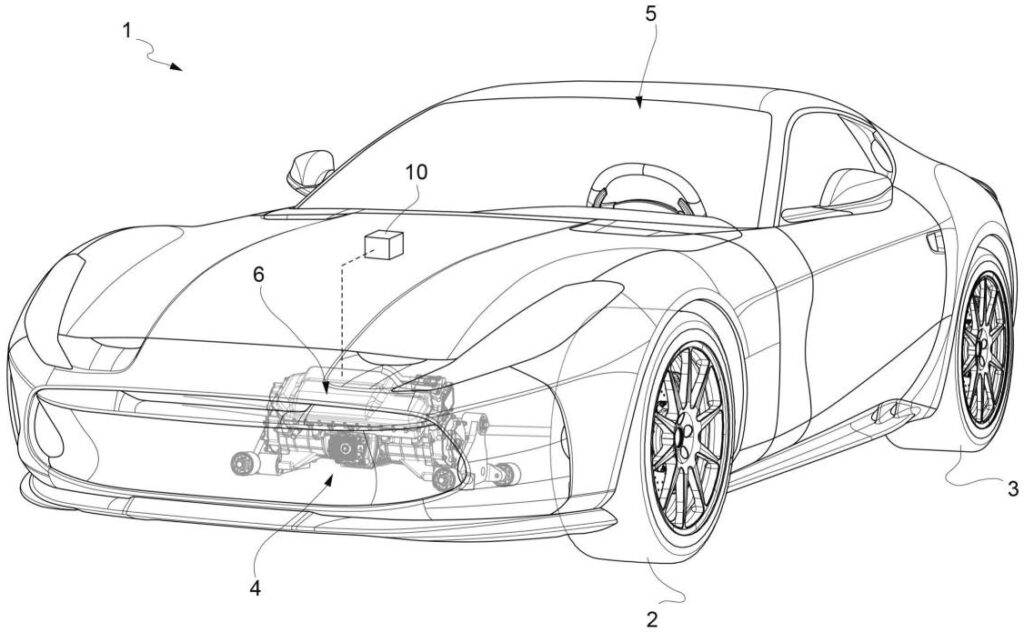

For the first time ever on a Ferrari, of electric turbo technology (e-turbo), which, with an electric motor installed between the turbine and compressor of each turbo, allows for an extraordinary specific power output and instantaneous response from low down in the rev range.

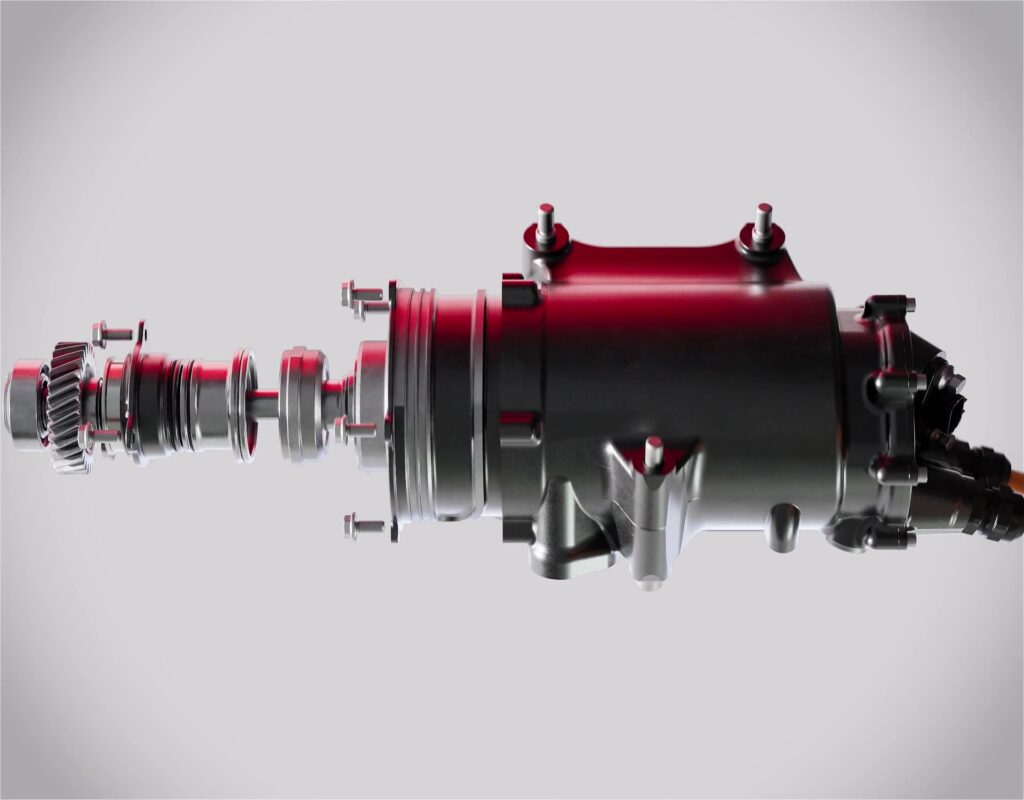

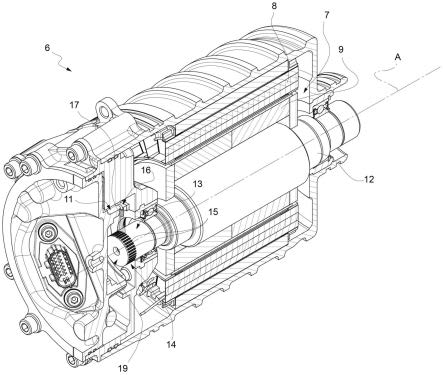

The electric motors used for the F80 are the first units developed, tested and manufactured entirely by Ferrari at Maranello, all with the specific goal of maximising performance and reducing weight. Their design (with two on the front axle and one at the rear of the car) draws directly from Ferrari’s experience in racing; specifically, the stator and rotor in a Halbach array configuration (which uses a special layout of the magnets to maximise magnetic field strength) and magnet sleeve in carbon fibre.

The rotor adopts Halbach array technology to maximise magnetic flux density and minimise weight and inertia. The carbon fibre magnet sleeve, on the other hand, has been used to raise maximum motor speed to 30,000 rpm. The concentrated winding stator reduces the weight of copper used for the end windings, while the Litz wire minimises high-frequency losses. The Litz consists of multiple insulated strands instead of a single wire, reducing the ‘skin effect’ and allowing the current to flow uniformly through the entire cross section of the wire to minimise losses. The resin coating for all the active parts of the stator improves heat dissipation.

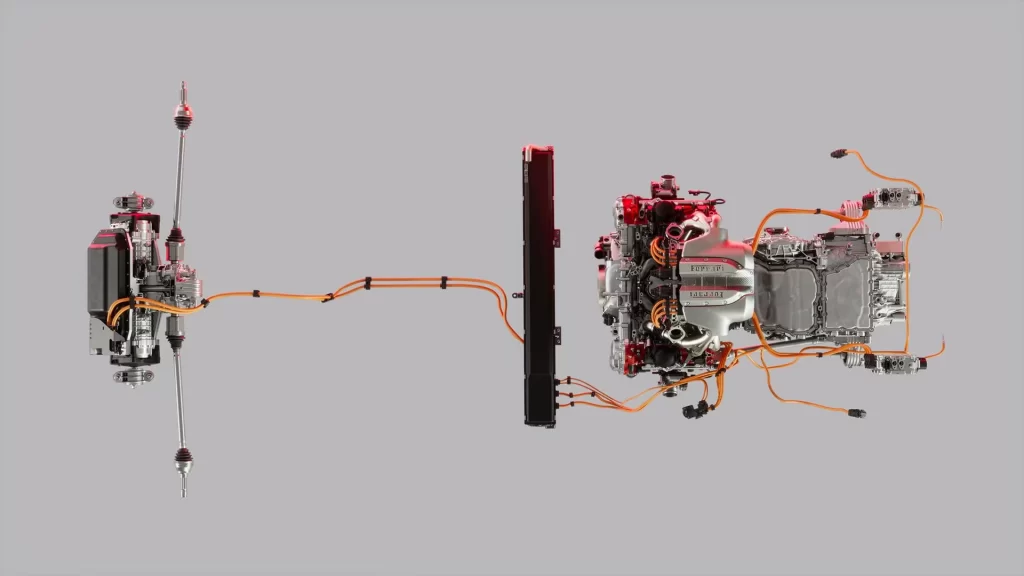

REAR ELECTRIC MOTOR (MGU-K)

This performs three functions: starting the internal combustion engine, recovering energy to recharge the high voltage battery and supplementing the torque of the engine in certain dynamic conditions.

Operating voltage: 650 – 860 V

Peak power Regenerative braking: 70 kW (95 cv); ICE assist: 60 kW (81 cv)

Peak torque: 45 Nm

Maximum engine speed: 30,000 rpm

Weight: 8.8 kg

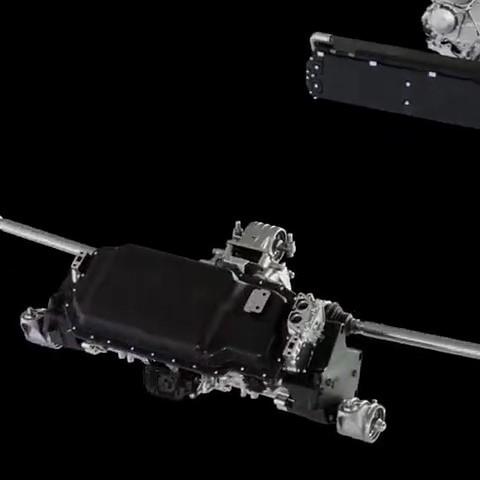

FRONT AXLE ELECTRIC MOTOR

Operating voltage: 650 – 860 V

Peak power: 105 kW (142 cv) for each of the two electric motors

Peak torque: 121 Nm

Maximum engine speed: 30,000 rpm

Weight: 12.9 kg

HIGH-VOLTAGE BATTERY

Maximum voltage: 860 V

Maximum power (charge/discharge): 242 kW

Energy: 2.28 kWh

Maximum current: 350 A

Power density: 6.16 kW/kg

Weight: 39.3 kg

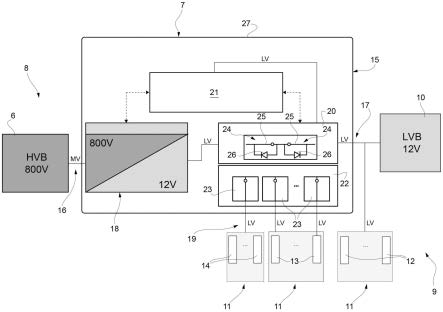

A DC/DC converter transforms DC current at one voltage to DC current at a different voltage. This innovative technology makes it possible to use a single component to handle three different voltages simultaneously: 800 V, 48 V and 12 V.

Using the direct current produced by the high-voltage battery at 800 V, the Ferrari converter generates direct current at 48 V to power the active suspension and e-turbo systems, and 12 V direct current to power the electronic control units and all other electric ancillaries on the vehicle. Innovative resonant technology allows this component to convert current with no latency with a conversion efficiency in excess of 98%, so that it behaves to all intents and purposes as an accumulator. This component eliminated the need for a 48 V battery, saving weight and simplifying the layout of the electrical system.

ah yes. more battery subscriptions…

dear ferrari fans. please go read up on the cost-usage-replacement cycle

of the 918 spyder, mclaren p1 and laferrari.

if you are not shocked by that.

go read about “negative equity” in the EV world…

its a grift.

0