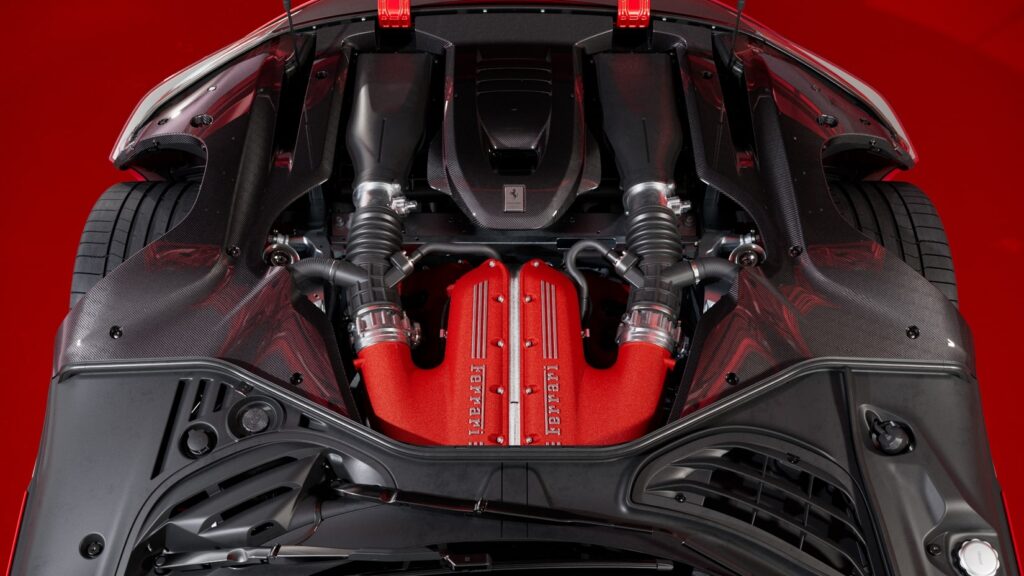

The F140HD engine equipping the Ferrari 12Cilindri is the new version of the iconic naturally-aspirated Ferrari V12. The engine can unleash up to 830 cv while its max revs have been increased to 9500 rpm by adopting challenging and innovative solutions.

The engine features modified components and software, some of which were already adopted on the special series 812 Competizione, ensuring it tops its category in terms of performance. To allow the V12 to rev so high, the engineers worked to reduce the weight and inertia of the engine’s components, adopting titanium con rods, which guarantee a saving of 40% in rotating mass compared to steel with the same mechanical resistance. A different aluminium alloy was used for the pistons, making them lighter than on previous applications. Further weight reduction was gained by the adoption of a rebalanced crankshaft which is 3% lighter.

The valvetrain with sliding finger followers was developed specifically for the V12 with the aim of reducing mass and availing of more high-performance valve profiles. The sliding finger follower, which is steel with a Diamond-Like-Carbon (DLC) coating, transmits the action of the cam to the valve using a hydraulic tappet as the pivot for its movement. The use of DLC reduces the coefficient of friction at critical points, significantly improving the mechanical efficiency of the engine.

Sound is pivotal to marrying the comfort, luxury and exhilarating driving emotions typical of a Ferrari V12: to this end, every element of the intake and exhaust lines were optimised. Equal-length exhaust tracts, the 6-in-1 manifold for every cylinder bank and the innovative design of the central sections has resulted in Ferrari’s typical V12 howl made up all of the noble combustion orders.

Altering the position of the resonators on the intake line has also changed the pressure waves, resulting in a richer range, particularly in terms of the middle frequencies.

The result is a cleaner, fuller sound in all driving conditions, and especially in sportier situations.

Optimising the engine’s mechanical efficiency and that of the lubrication circuit is critical to delivering blistering performance and low fuel consumption. The calibration of the variable displacement oil pump allows the oil to circulate throughout the entire engine and then be recovered along with the vapours from the sump. A solenoid valve, controlled by the engine ECU in a closed loop, is used to control the pump’s displacement in terms of engine revs and pressure, delivering only the amount of oil required and thereby simultaneously saving a significant amount of energy. The new configuration of the oil tank and pump’s hydraulic circuit reduces losses to a minimum and optimises functionality in all operating conditions.

The gasoline direct injection system (GDI at 350 bar) comprises two petrol pumps and four rails with pressure sensors that provide feedback to the pressure control system. The electronic injectors can also control up to three injections per engine cycle. The ignition system is constantly monitored by the engine control unit which has a single and a multi-spark function. The ECU also controls combustion in the chamber to ensure that the engine is always working in peak thermodynamic efficiency conditions, using a sophisticated strategy that recognises the octane rating of the fuel in the tank to avoid knocking.

The new exhaust system, developed to allow the car to comply with the latest emissions requirements (EU6E, China 6b and Bin 50), introduces a ceramic catalytic converter coupled with a particulate filter. This is the most advanced emissions-reduction technology available and involved lengthy calibration of the software strategies.

For the very first time on a naturally-aspirated engine, an innovative software strategy was developed that can modify the maximum torque available as a function of the gear selected. This gives the driver the feeling of smooth, progressive pick-up as the transmission ratio increases, another vital factor in making the driving exhilaration delivered by the Ferrari 12Cilindri truly unique.

Innovative Aspirated Torque Shaping (ATS) has allowed the Maranello engineers to sculpt the torque curve in third and fourth gears using sophisticated electronic control that improves perception of the shape without impinging on acceleration, all to the benefit of driving pleasure.

The introduction of the new final drive furthermore keeps acceleration levels high and allowed the engineers to define a new torque curve shape for an aspirated engine.

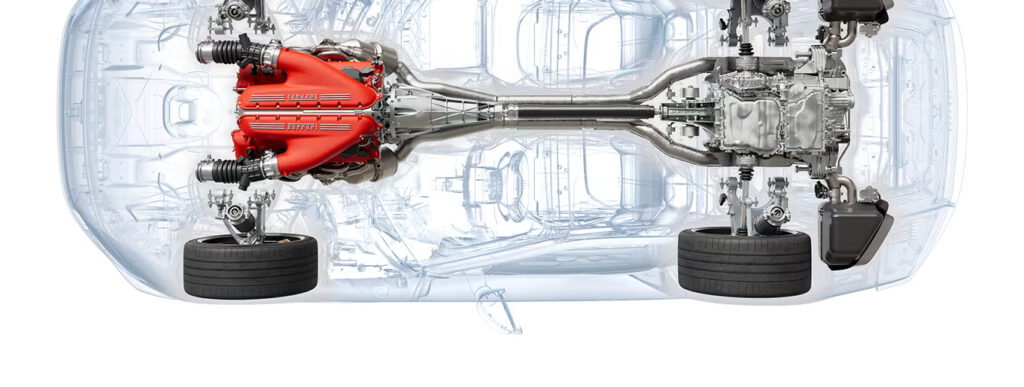

The Ferrari 12Cilindri sports the 8-speed DCT (Dual Clutch Transmission) that received such an unanimously rapturous welcome on other cars in the range, starting with the SF90 Stradale. Thanks in part to larger tyres on 21” rims, this solution delivers 5% shorter gear ratios in the lower gears and a 12% increase in torque at the wheels compared to previous V12 applications, all to the benefit of longitudinal performance under acceleration and gear shifting times (30% faster than the previous V12 berlinetta applications).

Performance under acceleration through the gears has been significantly improved and the introduction of the 8th gear improves range in motorway driving. The eight-speed DCT thus both improves efficiency and is more engaging in all gears.