Enovix announced its latest advancement called BrakeFlow™ technology, an intra-cell system that significantly increases tolerance against thermal runaway from internal shorts, without compromising high energy density.

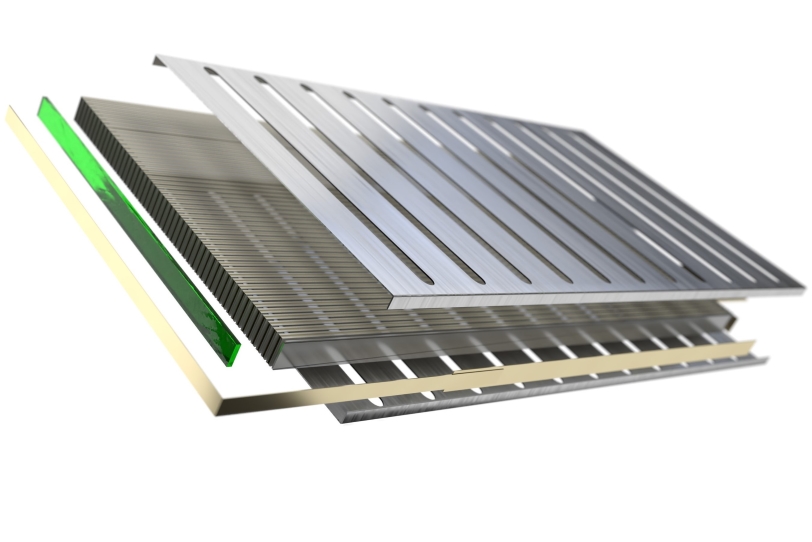

Unlike conventional “jellyroll” Li-ion cell architecture, where energy density and safety can be in conflict, the Enovix 3D cell architecture incorporates multiple intra-cell features to improve electrical, physical and environmental abuse tolerance over conventional wound Li-ion cells. In addition to BrakeFlow, the Enovix cell architecture:

- Provides better Lithium Plating Protection over graphite anode cells due to a 100% active silicon anode (140mV higher lithiation potential)

- Enables hotspot reduction and heat dissipation due to excellent thermal conductivity (nearly 5X cell thermal conductivity compared to similar pouch cells);

- Includes enhanced protection from physical abuse, including crush, pinch and nail penetration due to its mechanical internal constraint system; and

- Is designed to limit movement of the anode, cathode and separator due to internal “pinning,” which is a known source of internal shorting in conventional Li-ion batteries.

BrakeFlow technology will become part of the company’s automatic tooling and production set at its Fremont factory, Fab-1. The company anticipates BrakeFlow will be available in its battery cells in 2023.