The dyno can test electric motors between 24 – 144 volts and 0.5 to 60 kw, and is a turnkey solution that can be set up and fully operational within hours.

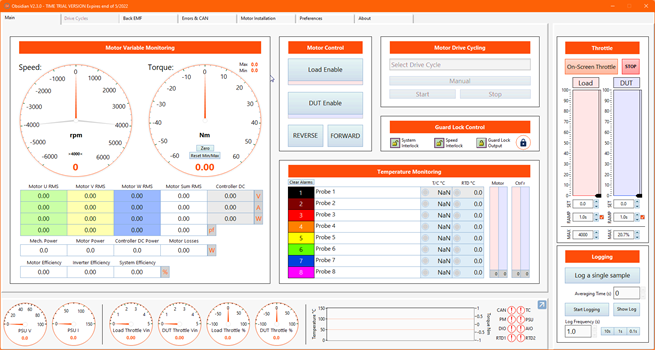

The monitoring software that works alongside the dyno rig gives live speed, torque, voltage and power indictors as well as on-screen throttle control.

It has an easy to use interface that allows you to run multiple real world simulations and export all the data to Excel, or whatever package you choose.

High speed communications to inverters and hardware

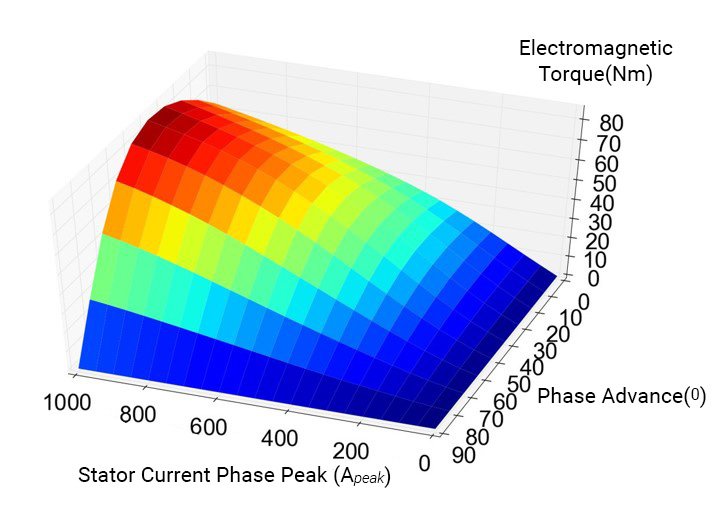

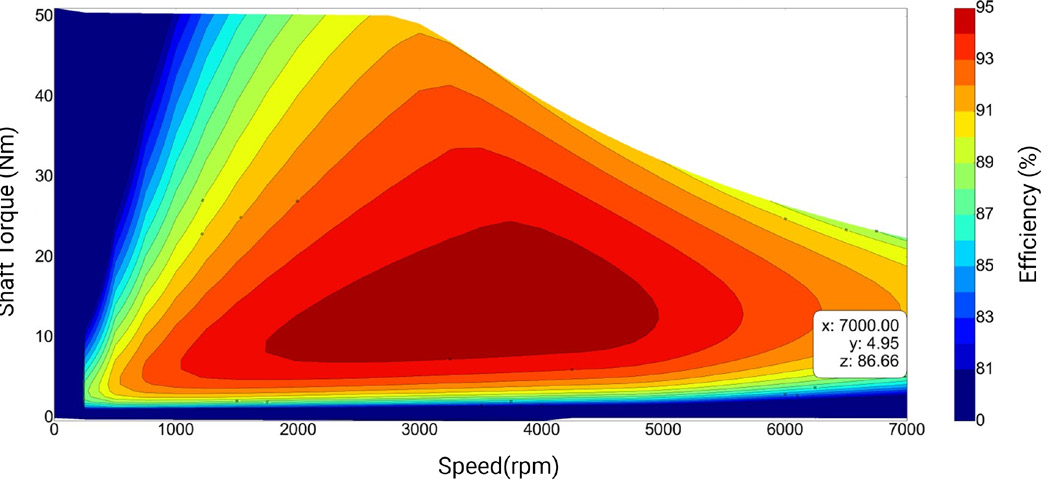

Automated efficiency contour plots, drive cycles and torque-speed plots

Automated control of torque, speed, voltage and current

Manual control option also available

Live data and graphical information for instant feedback