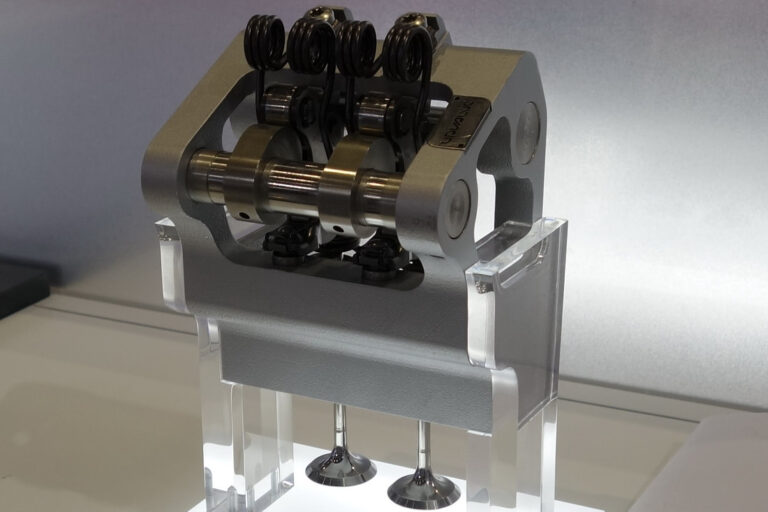

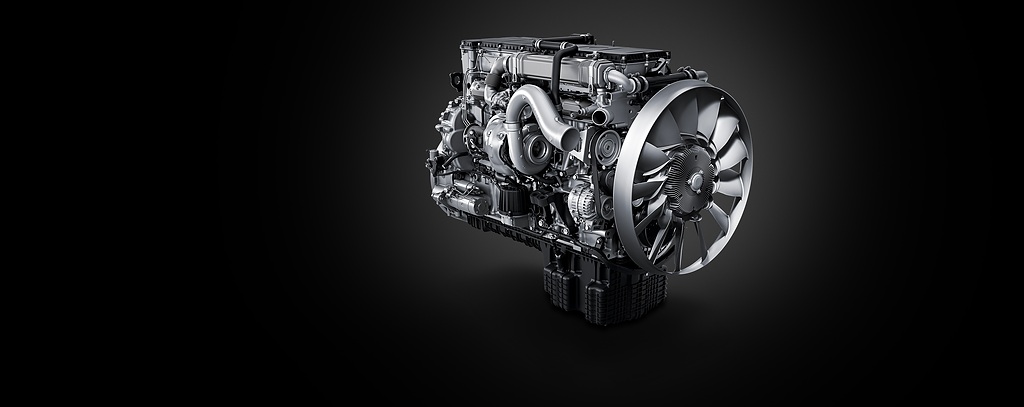

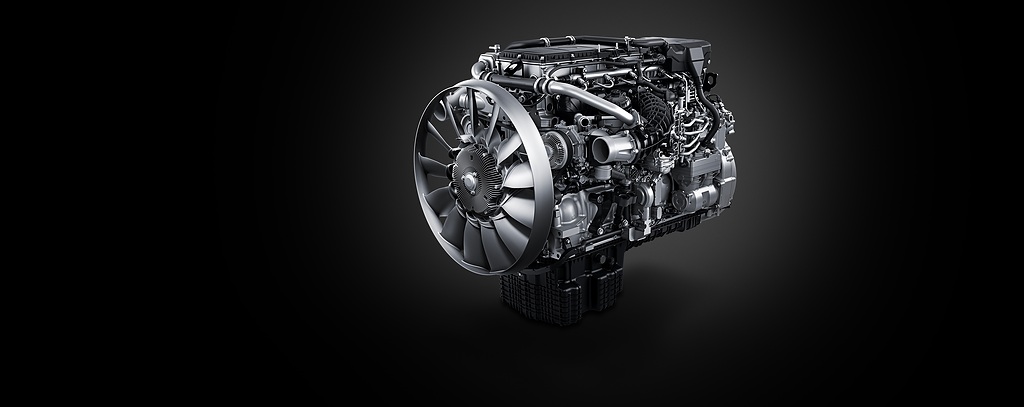

The improvements in efficiency for the third generation of the OM 471 are the result of a number of engine innovations. For example, the geometry of the piston recess, the injection nozzle design and the parameters of the cylinder head relevant for gas exchange were subject to an extensive optimization process. In this way, the compression ratio of the six-cylinder in-line engine has been increased from 18.3:1 to 20.3:1, this leads to more efficient combustion with a peak ignition pressure of 250 bar.

The second turbocharger variant is designed for high performance and a high engine braking force and is ideal for use in the heavy-duty- and construction sector with an engine rating of up to 390 kW (530 hp). For the lower and medium performance levels of the OM 471, the maximum fuel saving compared with the previous generation is up to four percent, and for the upper performance levels up to 3.5 percent. Thanks to lower consumption, both operating costs as well as CO2 emissions are reduced. The high-power variant is also used in the lower performance levels for the construction applications of the Arocs.

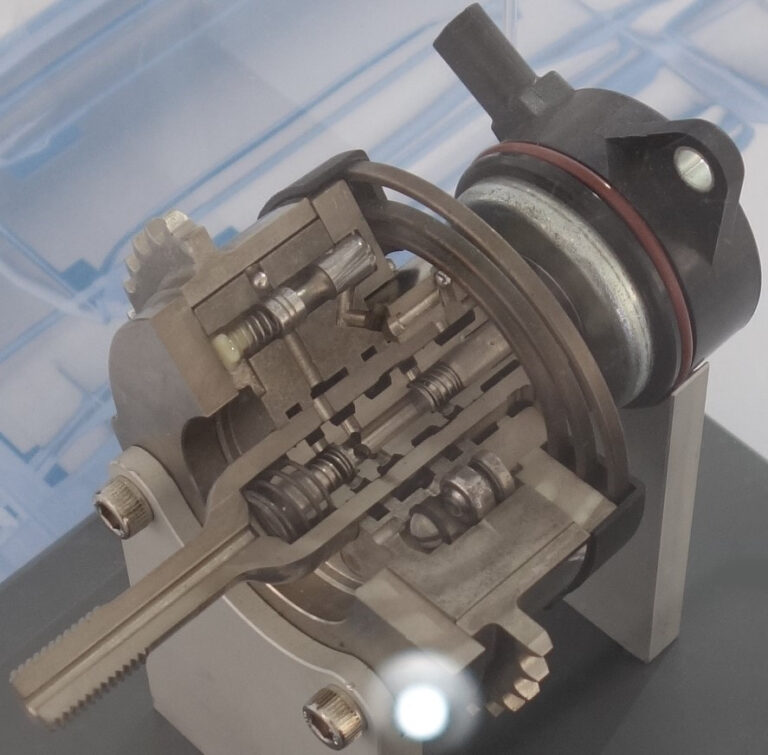

Friction reduction is the third important lever for improving fuel efficiency. For this purpose, the third-generation OM 471 has a newly developed engine oil pressure control valve. It is installed behind the engine oil pump and in front of the oil thermostat. An electrical actuator enables characteristics map-controlled use of the pressure-reducing valve. Available reductions in engine oil pressure are determined in a complex matrix that takes into account all engine components and their specific requirements, such as lubrication or cooling. A newly-developed engine oil with low viscosity enhances oil pressure control– it improves fuel efficiency without reducing oil change intervals or increasing the wear on affected engine components.

The exhaust gas aftertreatment system, which has been completely revamped and adapted to the new combustion and control system of the OM 471, also helps improve fuel efficiency. The system limits the counterpressure and also increases the uniformity index of the AdBlue, which leads to improved NOx conversion and lower fuel consumption. The NOx sensors together with the closed and adaptive NOx closed-loop control circuit and a predictive SCR temperature model have enabled emission stability to be improved even further. It is even compliant with the strictest emission standards, such as Euro VIe, which call for effective limitation of exhaust gas emissions over the entire normal service life of a vehicle under normal usage conditions.

The new PowerShift Advanced automated transmission control enables faster and smoother moving off and acceleration in many situations thanks to precise gear selection. Faster gear changes reduce the torque interruption time by up to 40 percent in the upper range. Accelerator pedal parameterization has also been further optimized: Increased sensitivity in the lower pedal travel enables significantly more sensitive maneuvering, while the direct response time in the upper pedal travel results in increased dynamics under high load requirements. It also makes it easier to drive around, and accelerate out of roundabouts.

Another highlight is the extended Top Torque range. Available for engine output levels 330 kW (450 hp) and 350 kW (476 hp) in conjunction with the G281 transmission, a powerful 200 Nm torque is available to the crankshaft in gears 7 to 12 in the “A Standard” program. “Power at the press of a button” for more performance that is available when you really need it – for example on highway on-ramps or when overtaking. All the while saving diesel. More added value that pays off in every respect for drivers and fleet operators alike.