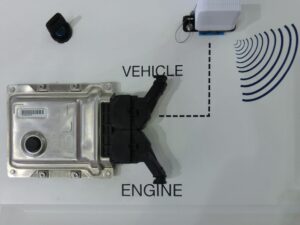

Eaton’s fuel burner air source is designed to deliver precise and efficient combustion plus cooling air to Tenneco’s Cold Start Thermal Unit (CSTU) fuel burner.

The CSTU air source allows airflow to be efficiently and precisely controlled to maintain optimal aftertreatment temperatures.

Eaton’s electrically-driven, TVS V180-based blower is part of a fully-optimized exhaust thermal management system developed in partnership with Tenneco to help engine manufacturers meet future emissions regulations.

Positive displacement pump

Integrated 12-volt or 24-volt electric motor drive

Flexible motor sizing

Rapid response time

Precisely controlled air flow

Multiple vehicle integration options

| Compressor Type | Positive Displacement (Roots-style) |

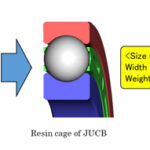

| Bearings | Sealed / Greased and oil lubricated |

| Ambient Operating Temp (°Celsius) | -40 to 130 |

| Input Voltage (Vdc) | 18-32 (24V nominal) |

| Mass (kg) | 5-8 (depending on motor options) |

| Max Speed (rpm) | 4000-6000 |

| Transient Response Time (seconds, t63) | 0.25 |

| Max Pressure Ratio | 1.6 |

| Volumetric Flow (m3/hr) @ 4000 rpm and 1.5 Pressure Ratio (PR) | 28 |

| Motor Power (Watts) | 1100 |