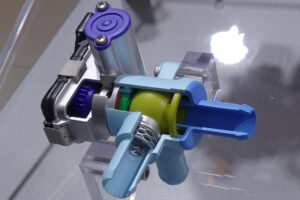

During engine idle or part load operating conditions, fuel injected into the combustion cycle may not be sufficient to maintain gas temperatures. Generating engine back pressure is a method for increasing engine out temperature. Back pressure can be achieved by utilising a valve after the turbocharger.

Partially obstructing the flow creates load on the engine, increasing the exhaust temperature. Reducing the expansion ratio over the Turbine wheel reduces turbocharger speed. Oil pressure is related to engine speed, while higher oil pressure combined with lower rotor speed increases the compressor side oil leakage risk. Both exhaust brakes and ETV can push the compressor operating point towards the choke side of the compressor map. This results in a reduced pressure behind the wheel for a given speed when compared with engine idle conditions.