The AIBA facility is located on Continental’s oldest test site Contidrom.

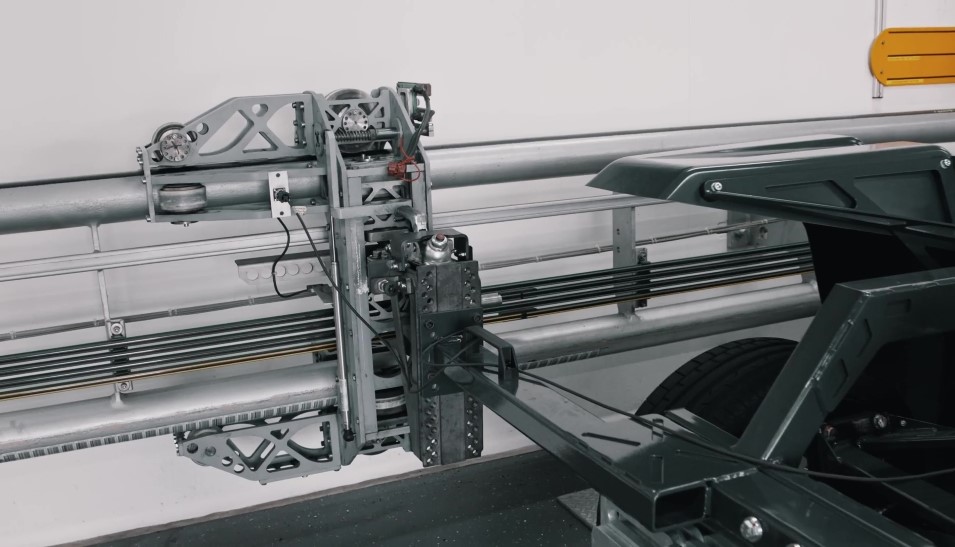

Continental has carried out more than a million trips on its fully automated tire braking test facility known as the AIBA (Automated Indoor Braking Analyzer) since 2012. The facility enables precisely reproducible test processes to check the performance of new car and van tires on different road surfaces – dry and wet – under laboratory conditions. Its advantages lie not only in the special test environment. In the facility, unmanned, rail-guided vehicles are automatically accelerated to speeds of up to 120 km/h along a track almost 100 meters long. They are then braked autonomously on a 75-meter-long braking track. No fuel is required for this process. This is because the acceleration takes place with the help of an electromagnetic linear drive borrowed from modern roller-coaster technology. The AIBA facility also eliminates the need for the many kilometers of driving that are required on normal test tracks for starting off and pulling away.

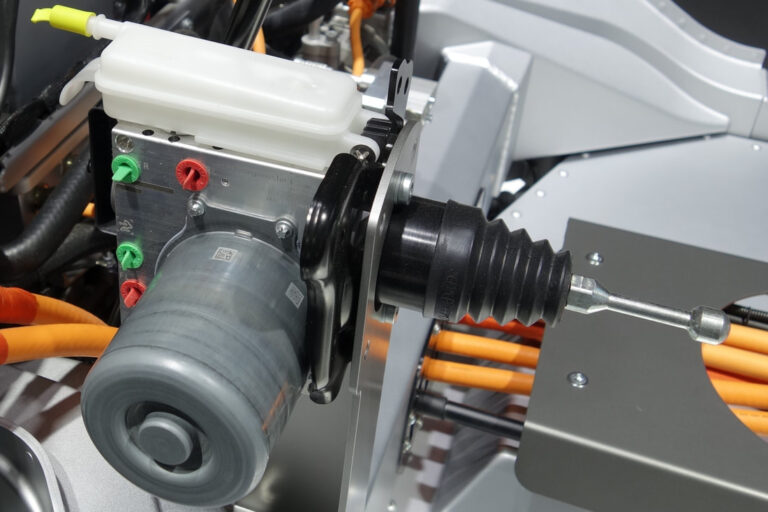

In contrast to virtual simulations, the fully automated tire braking test facility uses real vehicles on real road surfaces. This enables efficient, precise, and comparable tire tests – regardless of changing external influences such as temperature, wind, and sunlight. The braking tests can even be carried out independently of vehicle-specific properties. Continental has also been testing tires since 2022 with the help of the Analytical Vehicle AIBA (AVA). This is a fully electric, driverless test vehicle developed in-house that can be used instead of a serial car or van.

The physical tests in the AIBA facility are an integral part of extensive testing procedures that Continental uses to ensure that its tires offer optimum performance on dry, wet, snowy, and icy roads. Before the actual start of production, new tire models cover around 25 million kilometers a year on roller drum test rigs and test tracks. This corresponds to around 625 orbits around the earth. This also includes test drives to determine the subjective road performance of tires with professional test drivers, which are carried out on Continental’s worldwide test tracks.

The innovative tire braking test facility also supports Continental’s sustainability strategy. Over the past 12 years, valuable resources have been saved thanks to the AIBA facility and the electromagnetic linear drive. Around 166,000 kilometers needed on normal test tracks for starting off and pulling away have been avoided. This has saved 16,600 liters of fuel and almost 40 tons of CO2. The electricity for the AIBA braking test facility has been generated entirely from renewable energy sources since the end of 2020. Since then, Continental has been using it at all its production and test locations. To this end, the company obtains guarantees of origin following the criteria of the global RE100 initiative.