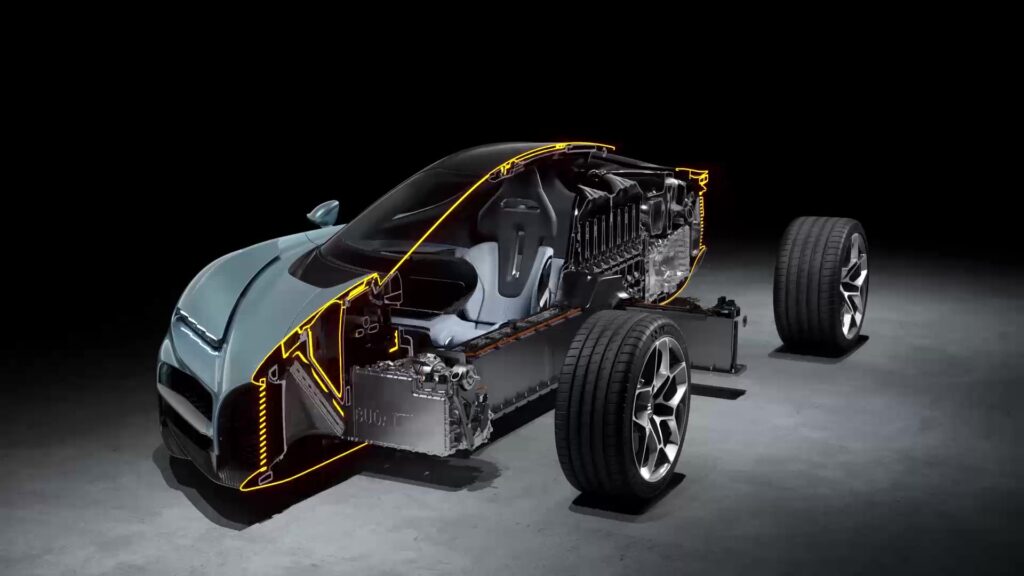

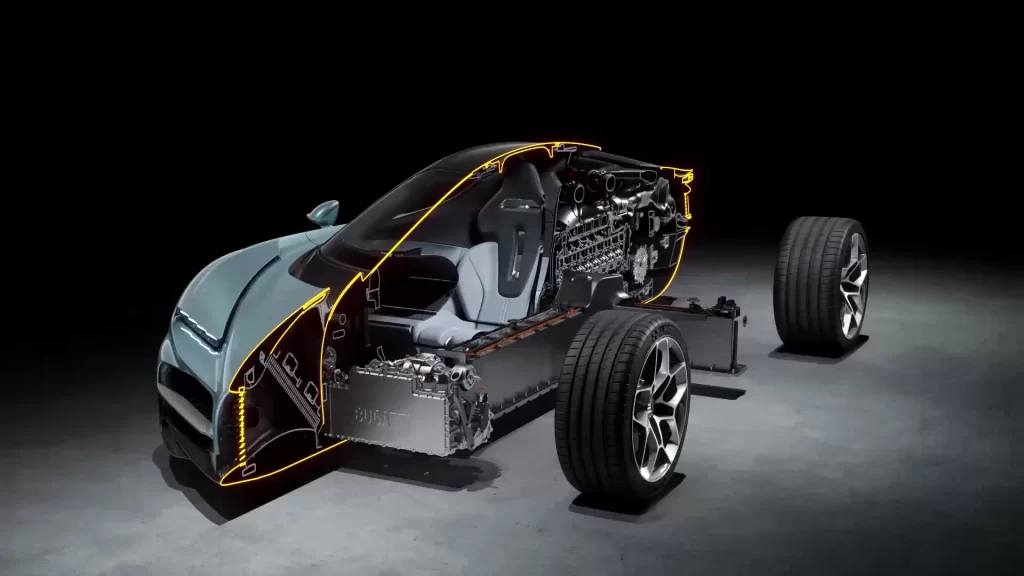

This next-generation Bugatti hyper sports car is powered by an all-new 8.3-liter naturally aspirated V16 engine – engineered with the help of Cosworth – paired with a front e-Axle with two electric motors and one electric motor mounted at the rear axle. In total, the Tourbillon produces 1,800 hp with 1,000 from the combustion engine itself and 800 hp from the electric motors.

Cosworth elected for a cross-plane crank design with 90-degree bank angles and dry sump. Weighing just 252kg in total – lighter than the naturally aspirated Aston Martin Valkyrie V12 – steps were made to optimise weight throughout the engine, including titanium connecting rods and a carbon fibre inlet plenum. The overall length of the crankshaft is 900mm, made from a single billet, with a total engine length just shy of 1m.

The electric motors are powered by a 25 kWh oil-cooled 800V battery housed in the central tunnel and behind the passengers. With four-wheel-drive and full torque-vectoring, it offers ultimate traction and agility. The front e-axle houses two electric motors, with a further motor on the rear axle, for a total of 800 hp from the electric powertrain system. The electric powertrain, with the electric motors spinning up to 24,000 RPM and a fully integrated dual silicon-carbide inverter. The e-axles are delivering over 6 kW per kg of e-axle mass, including inverters, motors and gearboxes. While power, throttle response and torque-fill are priorities for the electric powertrain, the relatively large energy content of 25 kWh allows for a very usable all-electric range of more than 60 km / 37 miles.

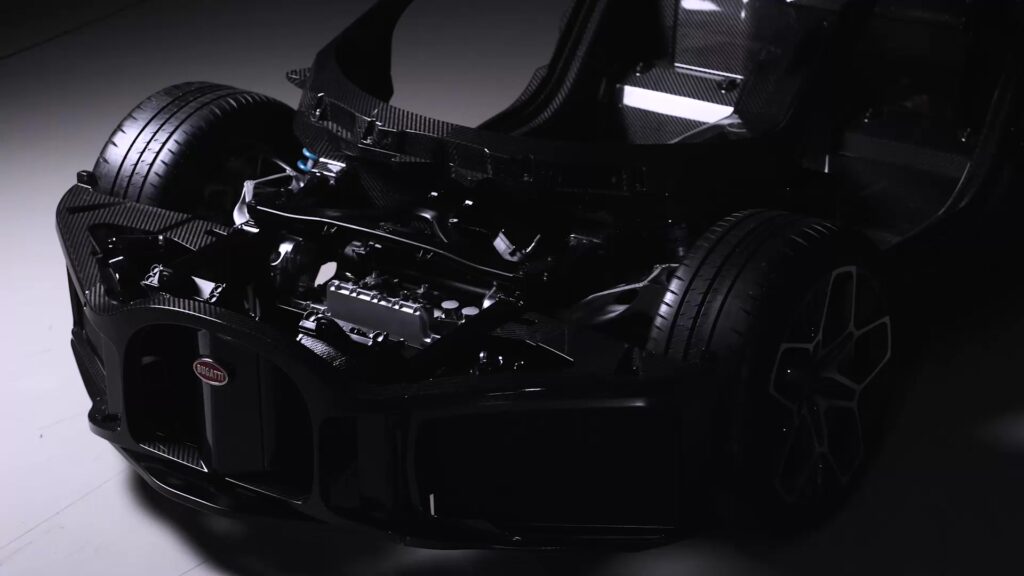

The Tourbillon is designed around entirely new chassis and body structure. The structure is made from a next-generation T800 carbon composite, which incorporates a number of weight-saving innovations, such as integrating the battery as a structural part of the monocoque and an unprecedented crash composite rear diffuser. The front composite air ducts that flow through the front of the car are also integral to the structure, ensuring that each and every part of the rigid, lightweight structure is optimized. For example, the front and rear frames exhibit low pressure thin wall aluminum casting and 3D printed structural braces, contributing to a structure that is significantly lighter and stiffer than its predecessor!

The completely new chassis integrates multi-link suspension front and rear, forged from aluminum, moving on from the double wishbone steel construction found in the Chiron. By opting for a new organic-designed suspension arm and upright, 3D-printed in aluminum, engineers have saved 45% in suspension weight compared with the Chiron. The rear also features an AI-developed 3D-printed hollow airfoil arm to enhance vehicle dynamics and aerodynamic performance.

Much of this aerodynamic equilibrium is thanks to the new diffuser concept, which starts to climb from just behind the passenger cabin, rising at an ideal angle to keep the Tourbillon in perfect balance. The diffuser is built around a completely new crash concept, which is fully integrated within the structure of the diffuser itself, keeping it both enormously effective but also hidden from sight, enabling the open rear-end design.

At the heart of the Tourbillon’s design ethos is the iconic horseshoe, from which all lines of the car originate, shaping the central fuselage volume. Docked onto that left and right are the flying fenders that allow to stream air underneath the headlights to boost air mass flow into the side intakes. This intricate interplay of airflow is further exemplified by the frontal design, which, while maintaining the dimensions of a sculpted overhang, ingeniously houses an ultra-efficient cooling system that directs air through and out of the front bonnet, augmenting downforce while ingeniously packaging a sizable frunk in between the two radiators.

Within the new chassis, the new ultra compact and lightweight front e-axle with dual independent motors, including the dual-inverter, fits within the same package space that was available in Chiron, adding more complexity without requiring more space. Designers and engineers also freed up more storage space and a larger luggage component, as part of the clean-sheet chassis and body shell design, allowing owners to fit a set of bespoke Bugatti Tourbillon luggage.

This car, like ALL the others of its ilk, will need, (my best guess), 250,000USD

worth of batteries, in its third year of existence, regardless of mileage.

This whole concept is ten-years-late to the ‘race to the bottom’

in the “hyper-car olympics”

where they always talk about weight-saving percentages,

but never seem to ever talk about actual curb weight.

If one were to weight a chromoly lower control arm, they might find,

that it weighs about ~2kg. so 45% savings is 0.9kg

BUT THEN,

it weighs 4500 pounds (2041kg). thats what they ended with… !!!

oh but hey. be glad that your 5M$USD is going to pay for the ~1kg

they saved, printing out some aluminum control arms, here and there.

even if they all managed to shave 500kg! off the car, it would still be heavier, arguably slower,

ostensibly less reliable (and still ugly) compared to nearly every sports car in its category in the last decade.

honestly the whole rimac bugatti thing is so weird.

everyone thinks they can can do better than something like a basic corvette…

but then look over the past 30 years of endurance racing and see hows been winning…

a fool and their monies; soon departed