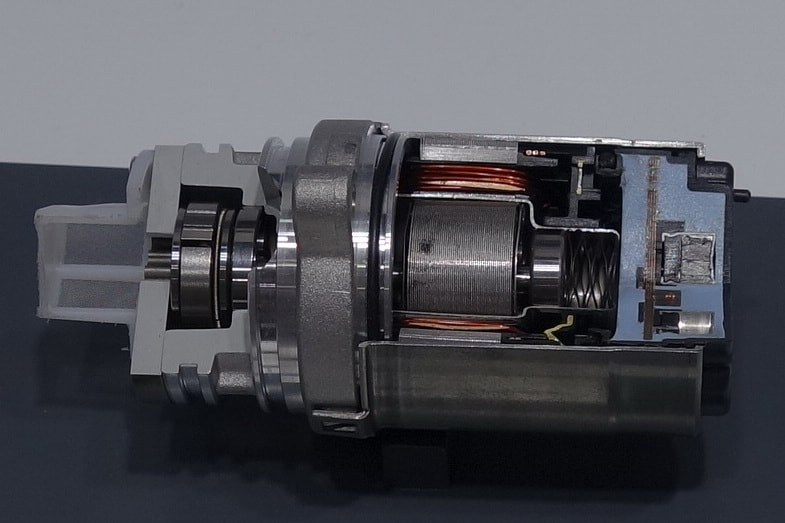

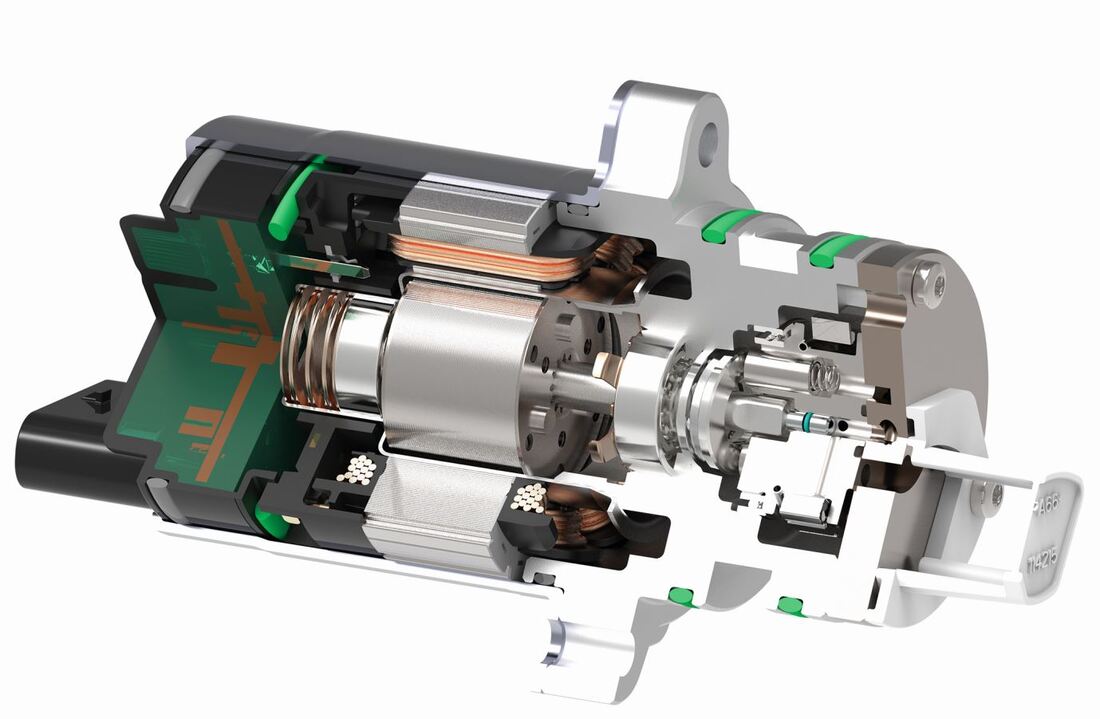

BLDC motor for improved durability as well as reduced size and improved thermal capability

Integrated ECU for reduced cost, improved packaging and robust electromagnetic compatibility due to removal of the cable harness

Dry stator and ECU to prevent any oil compatibility issues between oil, electronics hardware and interconnects

Wet rotor for the elimination of the dynamic radial seal between pump housing and motor shaft

Wet rotor for the elimination of the dynamic radial seal between pump housing and motor shaft

Sensorless motor control with the option of introducing a position sensor if required

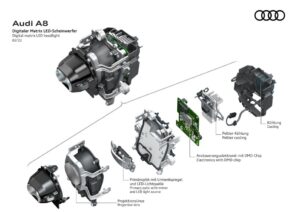

GenVI is a key enabler for an ECO mode due to the use of a BLDC motor with a more or less unlimited start/stop capability. In ECO mode, the motor is completely shut off in situations in which no torque transfer is needed. This reduces the energy consumption of the whole system.