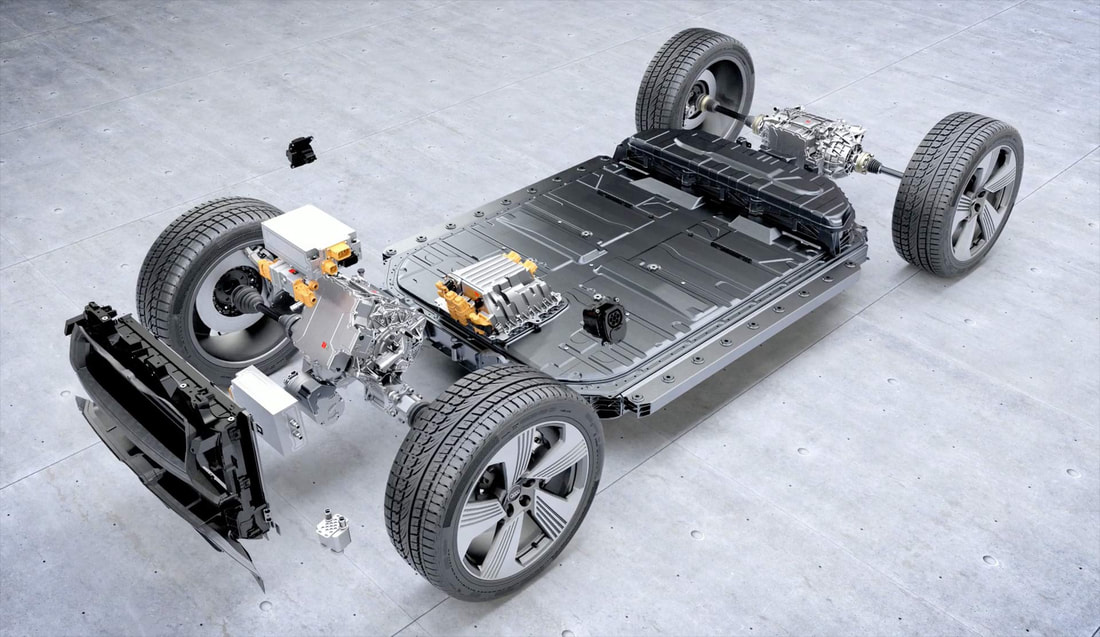

The battery system in the Audi e-tron is located beneath the cabin and is 2.28 meters (90 inches) long, 1.63 meters (63.6 inches) wide and 34 centimeters (13.4 in) high. It comprises a total of 36 cell modules in square aluminum housings, each of which is roughly the size of a shoe box. They are arranged on two levels, known as “floors” – a longer lower floor and a shorter upper one. At market launch, each module is equipped with twelve pouch cells having a flexible outer skin of aluminum-coated polymer. The battery operates with a nominal voltage of 396 volts and stores 95 kWh of energy.

A cooling system of flat aluminum extruded sections divided uniformly into small chambers has the task of maintaining the battery’s high-performance operation over the long term. Heat is exchanged between the cells and the cooling system beneath them via a thermally conductive gel pressed beneath each cell module. In what is a particularly resourceful solution, the gel evenly transfers the waste heat to the coolant via the battery housing.

A strong surround frame and lattice-type aluminum structure that holds the cell modules is designed to protect the battery block. A substantial aluminum plate provides protection against damage from flying stones or curbs, for instance. These measures demonstrate how the Audi engineers have developed the batter and cooling systems with safety in mind. The weight of the battery system including the housing pan with intricate crash structures is roughly 700 kilograms (1543.2 lb). It is bolted to the underbody of the Audi e-tron at 35 points. This increases the torsional rigidity of the body, which in turn integrates numerous aluminum parts such as the floor plate in the rear structure, the doors, as well as the hood and tailgate. The cabin features components made from heat-formed ultra-high-strength steel.