This solution is currently used in the production of both front and rear bumpers for Leapmotor’s new energy vehicles.

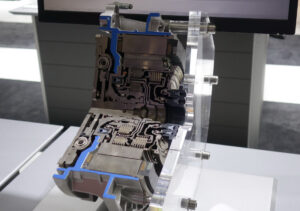

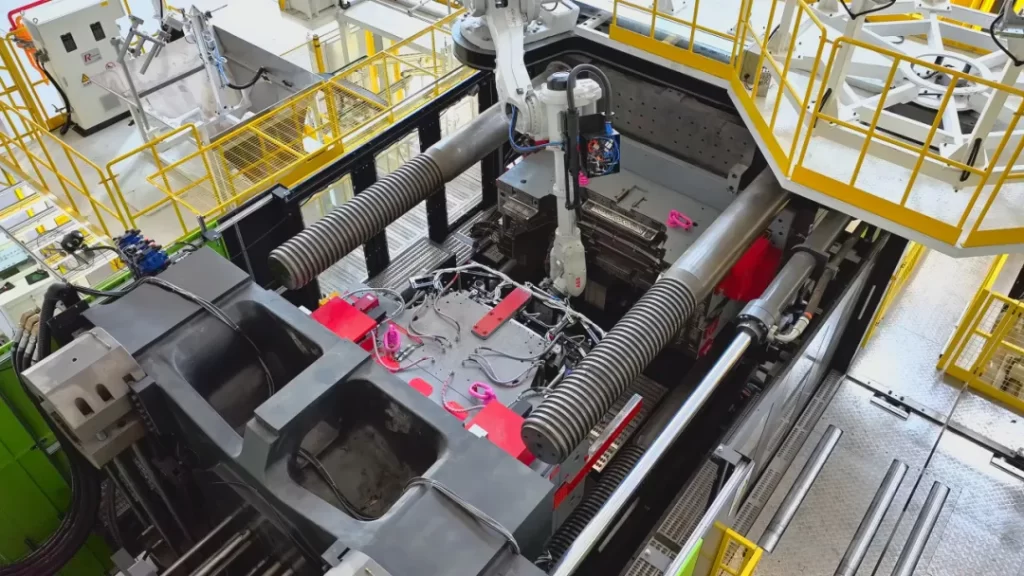

YIZUMI’s fully automated bumper solution integrates advanced injection molding technology with an automated production line, including—but not limited to—injection molding machines, automatic mold change systems, robotic automation, high-efficiency cooling systems, centralized feeding systems, MES digital management, and AGV intelligent logistics systems. This integration achieves complete process automation from raw materials to finished products.

The solution significantly enhances production efficiency by reducing the cycle time to less than 60 seconds, while ensuring extremely high product quality with a qualification rate exceeding 99%. Moreover, the repeat weight deviation is controlled within 0.3%, and equipment energy consumption remains at a low level of no more than 0.36 kilowatt-hours per kilogram of material.