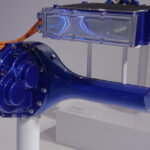

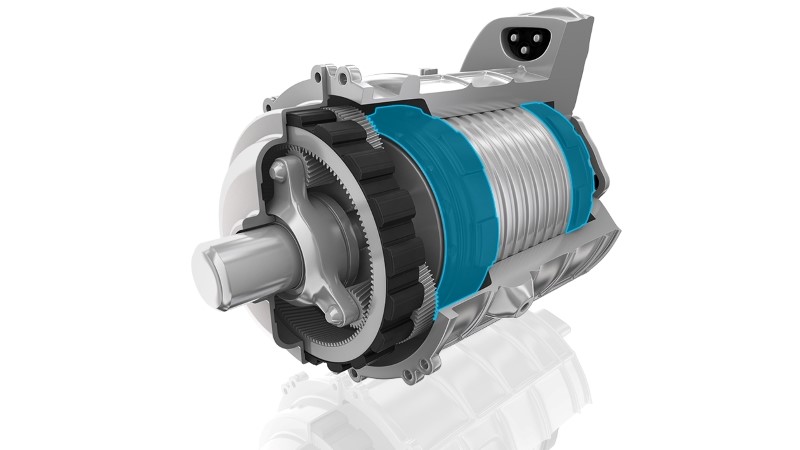

Vibracoustic has engineered a unique solution for the torque ripple caused by the fluctuating magnetic fields of e-motors in battery electric vehicles (BEVs). The multifunctional Stator Isolator prevents the transmission of axial, radial and torsional vibrations from the stator into its housing.

Vehicle manufacturers around the world continue to face new NVH challenges in the development of e-mobility platforms and powertrains. One such issue, excitations caused by torque ripple effects, occurring from the fluctuating magnetic fields in e-motors, can now be addressed with the innovative Stator Isolator from Vibracoustic. In contemporary BEVs, these torque ripples are transmitted from the e-motor to the gearbox, the housing of the e-motor and the gearbox (and thereby also to the vehicle body via the motor mounts), side shaft and into the wheel, resulting in multiple NVH-related issues, such as unwanted radiation of airborne noises in a wide range.

The Vibracoustic Stator Isolator isolates the stator from the stator/e-motor housing, providing axial, radial and torsional isolation. Designed to be integrated with e-motor cooling devices, the multi-functional product also provides an effective seal for circulating oil – essential for e-motor durability and safe operation.

The product is designed to be adapted to the existing stator carrier, with unique form-fit geometries that prevent rotation and provide an effective and durable seal. With a relatively high diameter and high tolerance requirements, the Stator Isolator presented the Vibracoustic team with some design-for-manufacture challenges.

Prototypes have already been designed and developed for customer development projects. While the Stator Isolator is initially intended for premium segment vehicles where NVH management is paramount, there is scope to integrate a similar solution in large-scale applications – essentially, any vehicle using e-motors.