Based on GMT, the composite GMTex® has been further developed for applications demanding high impact resistance, strength and durability. In the production of these high-performance thermoplastic composites, the basic materials of polypropylene (PP) or polyamide (PA) are reinforced with woven and randomly laid fibers (multi-layer glass fiber technology).

LFT-D (long-fiber thermoplastic direct compounding)

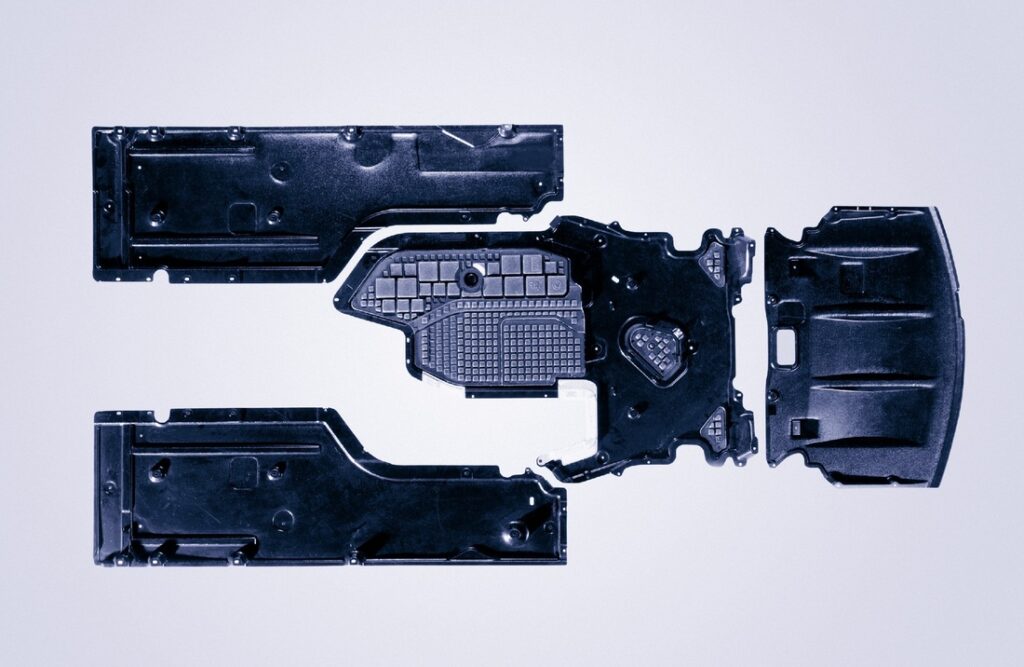

LWRT (Light Weight Reinforced Thermoplastics)

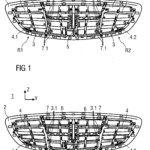

SymaLITE, a high-strength composite, has become established as an all-round material for extra-high weight savings combined with outstanding mechanical and physical characteristics. This product group of glass-reinforced thermoplastic mixed-fiber fleeces can be processed inexpensively into three-dimensional moldings by low-pressure pressing.

The entire underfloor structure of the new BMW 5 and 6 Series models is encased in four SymaLITE modules. This considerably improves the vehicle’s aerodynamics and thus reduces driving noise and fuel consumption. The new SymaLITE material concept also enabled weight savings of approx. 30 % to be achieved compared with conventional underfloor structures. The enclosed underfloor structure makes the use of PVC anti-corrosion protection unnecessary.