Toyoda Gosei Co., Ltd. is jointly developing a plastic pellet-type 3D printer together with S lab Inc., and will use it to increase the recycling of plastic waste in the company as part of its efforts to reduce waste.

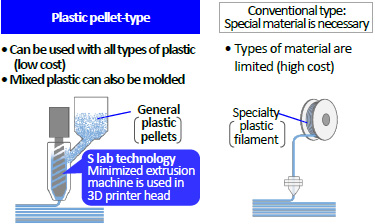

Plastic pallet-type 3D printer

The 3D printer being developed applies both S lab’s technology of extrusion machine and Toyoda Gosei’s expertise in plastic molding. While previous systems needed plastic filaments specially made for 3D printers, the new 3D printer can utilize plastic pellets, low-cost materials used widely for the molding of plastic products.

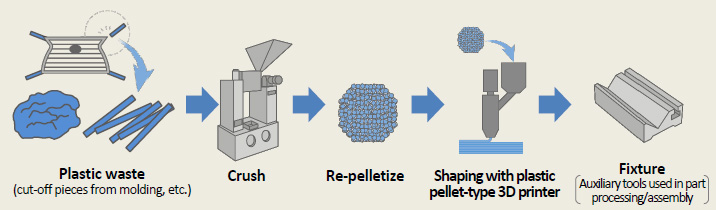

Toyoda Gosei is leveraging this 3D printer to boost recycle of the plastic waste generated in the production of automotive interiors and exteriors. Some of plastic waste does not meet strength and other specifications for reuse in automotive parts, so the company has been unable to recycle it in-house. The new 3D printer enables the re-pelletized plastic waste to be shaped without molds and gives it new life as fixtures or other tools.