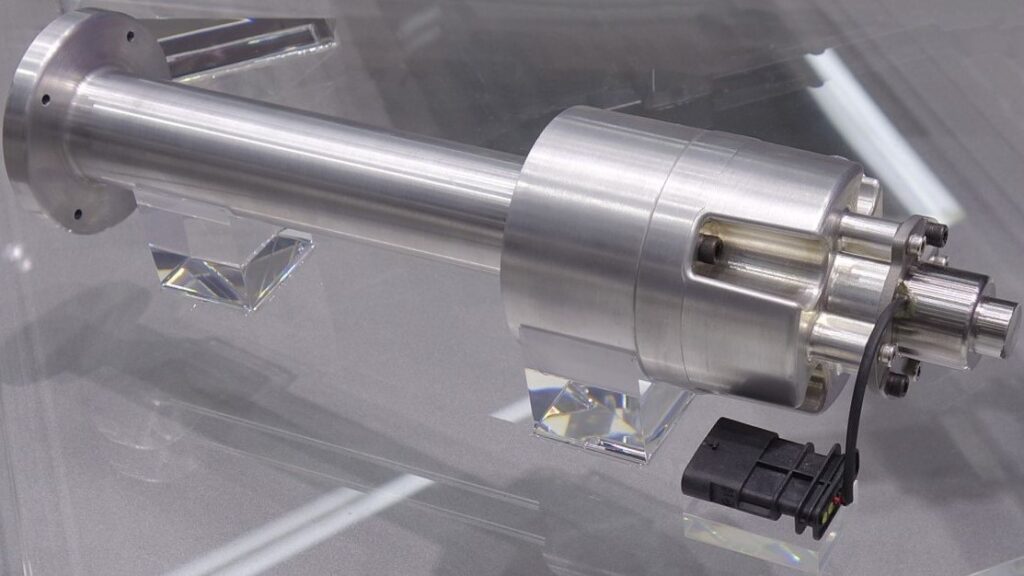

In the hydrogen path, the recirculation of unused hydrogen is the key lever for improving the efficiency. Theoretically, a continuously working pump would be sufficient for the mass transport, but such a solution is associated with a relatively high-power consumption.

Passive recirculation via controlled nozzles based on the Venturi effect is significantly more energy-efficient and space-saving. For this, various design solutions are available for transporting the residual hydrogen amounts, which depend on the respective operating points. Research has been done in the past on multistage and on adjustable nozzles, among other things. Intensive CFD simulations with multiple designs at Schaeffler show that an adjustable two-stage nozzle provides the best cost-to-benefit ratio. A decisive quality criterion for these nozzles – similarly to high-pressure fuel injection in an internal combustion engine – is the long-term reproducibility of precise volume control. The test bench tests conducted by Schaeffler in cooperation with an initial customer show that the Schaeffler nozzles offer this reproducibility.